Efficient. Precise. Engineered for Consistent Sugar Melting.

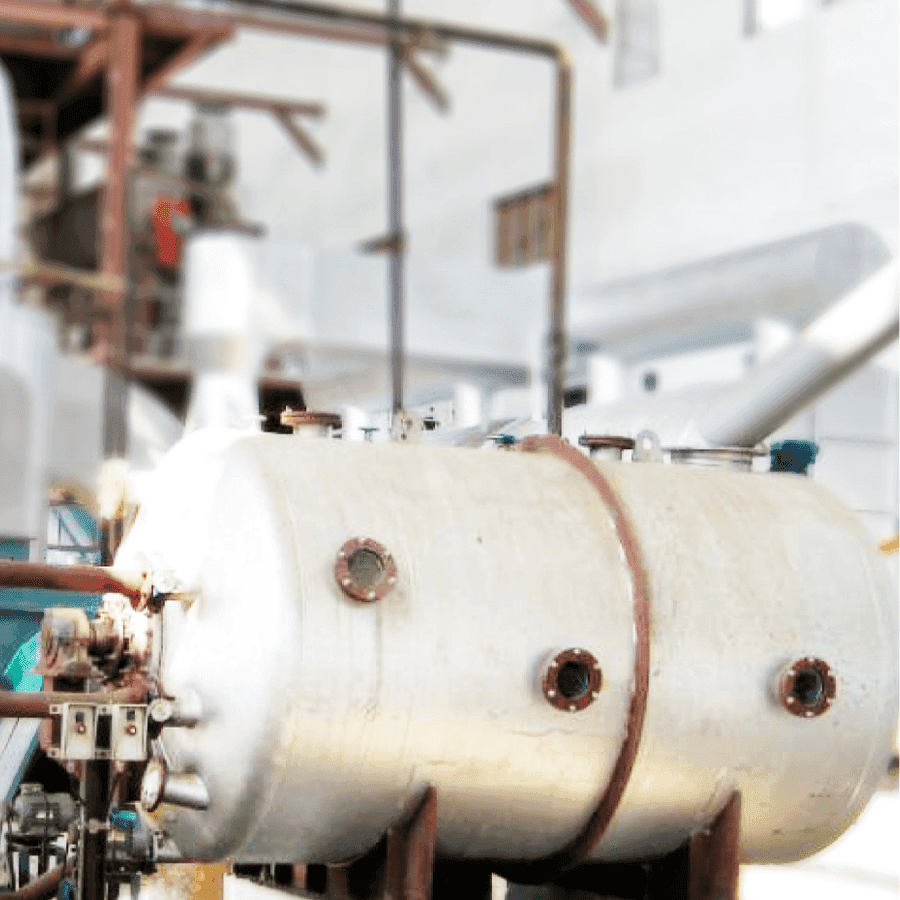

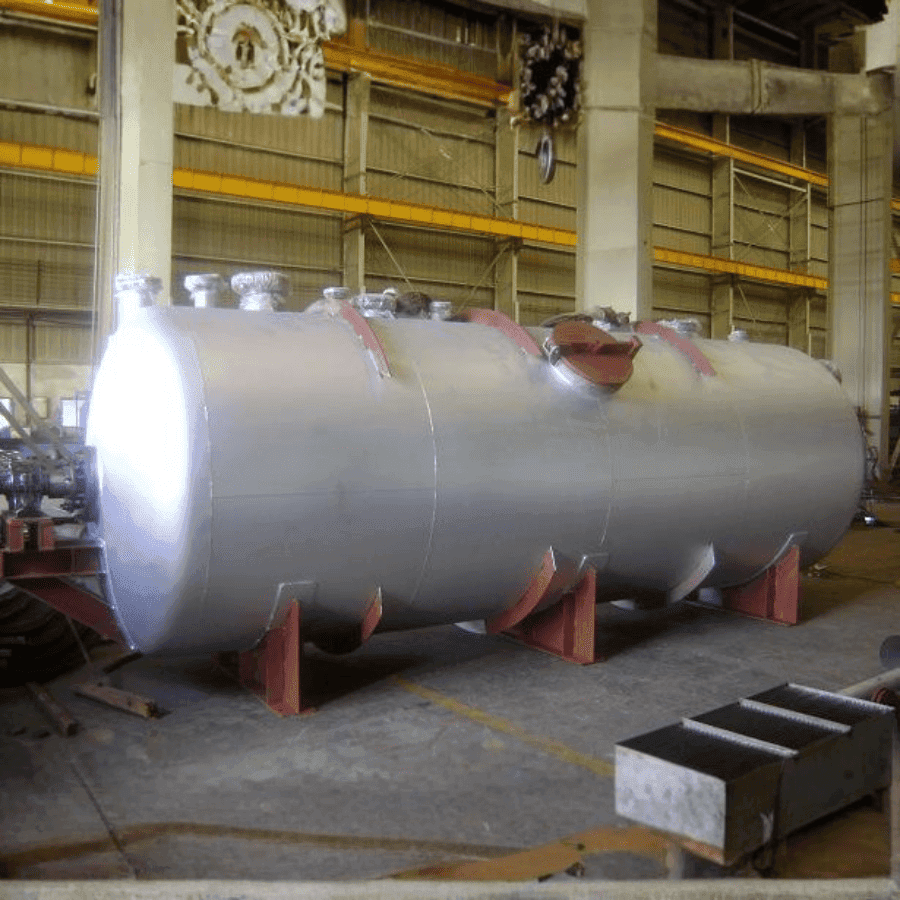

SED’s Sugar Melter is a specialized system designed for reliable and uniform sugar melting in refineries, cane, and beet sugar factories. Engineered to maintain precise brix and temperature levels, it ensures optimal melt quality using syrup or hot water as the melting medium. The unit operates effectively under vacuum or atmospheric conditions, utilizing low-pressure vapor for energy-efficient operation.

Its stainless-steel cylindrical design, combined with a horizontal paddle stirrer, eliminates undissolved crystals and short-circuiting, providing a smooth plug-flow system ideal for continuous industrial operations.

HowIt Works

Sugar Feeding & Mixing

Gentle Paddle Stirring

Low-Temperature Heating

Real-Time Monitoring & Automation

Key Advantages

Accurate Control Over Brix & Temperature

Automated monitoring ensures consistent melt quality for downstream processes.

Energy-Efficient Operation

Low-pressure vapor and vacuum operation reduce overall steam and power consumption.

Versatile Melting Options

Compatible with both syrup and water as melting media, adaptable to varying process requirements.

Plug-Flow Mixing Efficiency

Horizontal paddle stirrer prevents undissolved crystals and short-circuiting, delivering uniform and complete melting.

Accurate Control Over Brix & Temperature

Automated monitoring ensures consistent melt quality for downstream processes.

Versatile Melting Options

Compatible with both syrup and water as melting media, adaptable to varying process requirements.

Energy-Efficient Operation

Low-pressure vapor and vacuum operation reduce overall steam and power consumption.

Plug-Flow Mixing Efficiency

Horizontal paddle stirrer prevents undissolved crystals and short-circuiting, delivering uniform and complete melting.

Salient features

Stainless-steel horizontal vessel for durability and hygiene.

Horizontal paddle agitator ensures uniform plug-flow mixing.

Low-temperature vapor heating for energy-efficient operation.

Real-time brix and temperature monitoring with automated adjustments.

Capable of vacuum or atmospheric operation for flexible integration.

Applications Across Industries

SED’s Sugar Melter is ideal for:

Cane Sugar Refineries

Beet Sugar Factories

Continuous Sugar Processing

Energy-Efficient Plants

Why Partner with SED?

SED combines advanced thermal engineering, precise process control, and robust mechanical design to deliver consistent sugar melting solutions. The Sugar Melter ensures uniform product quality, optimized energy efficiency, and seamless integration into modern sugar production lines.

Frequently Asked Questions

Revolutionizing Sugar Melting. Setting New Standards.

Achieve uniform, efficient, and energy-conscious sugar melting with SED’s Sugar Melter - engineered for precision, reliability, and consistent product quality in modern sugar processing plants.