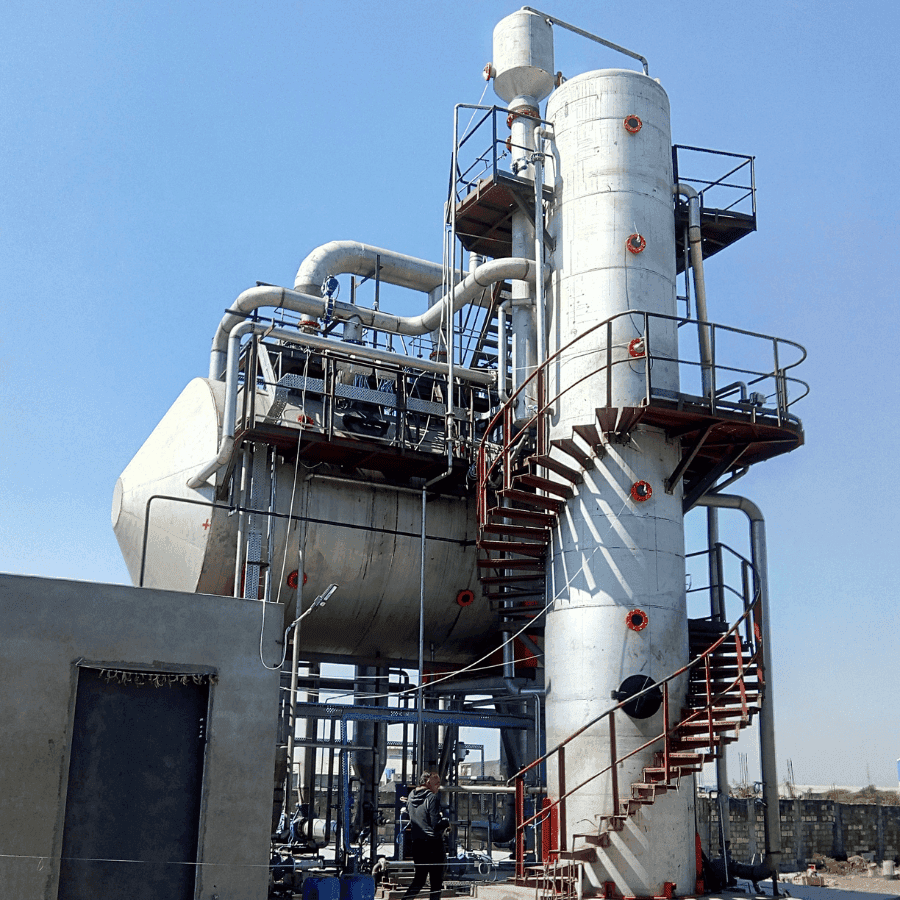

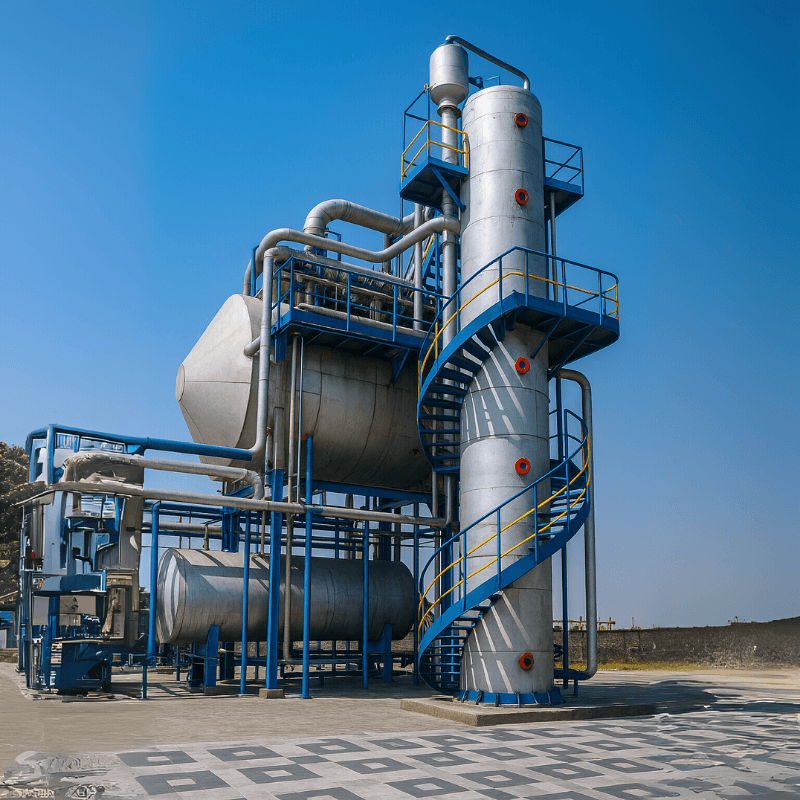

Forced Circulation Evaporator

A Forced Circulation Evaporator (FCE) concentrates highly viscous, high fouling, and crystalizing solutions using a tubular calandria and circulator/axial pump for efficient operation under vacuum or pressurized conditions.

Continuous circulation ensures uniform concentration and prevents the buildup of solids on the heating surface area, with MOC (materials of construction) - such as SS304, SS316, or Titanium - selected for fluid compatibility.

Working Principles

Heat Exchange

Circulation

Evaporation Terminology

Entrainment Separation

Why Is It Needed?

Enhances heat transfer efficiency through high-velocity circulation.

Minimizes scaling and fouling, ensuring cleaner operation.

Handles high-viscosity and pressurized fluids, ideal for tough applications.

Reduces maintenance and downtime, improving long-term reliability.

Enhances heat transfer efficiency through high-velocity circulation.

Handles high-viscosity and pressurized fluids, ideal for tough applications.

Minimizes scaling and fouling, ensuring cleaner operation.

Reduces maintenance and downtime, improving long-term reliability.

Salient Features

High Heat Transfer Coefficient

Enables rapid and efficient evaporation through superior heat transfer rates.

Compatible for High-Viscosity Liquids

Handles high-viscosity, highly corrosive, and crystallizing liquids with ease.

Less Fouling Rate

High liquid velocity minimizes solid buildup on heating surfaces.

Reduced Operational Cost

Enhanced efficiency and low fouling translate to long-term cost savings.

Ease of Installation

Skid mounted with inbuilt vapor separator facilitates ease in transportation and erection.

Automated Control

Advanced automation enables complete equipment control, preventive maintenance alarms, and enhanced safety measures, including CIP (Cleaning-In-Place), from the DCS (Distributed Control System) with no manual intervention.

24x7 Remote Operational Support

Continuous online monitoring, assistance, and control to ensure uninterrupted performance, quick troubleshooting, and optimal operation of equipment from anywhere.

Applications Across Industries

The SED Forced Circulation Evaporator is ideal for sectors requiring tough concentration solutions:

Chemical Processing

Food & Dairy

Pharmaceuticals & Nutraceuticals

Bio-based Industries

Specialty Chemicals

Why Partner with SED?

At SED, engineering innovation meets operational excellence. We collaborate with clients to deliver evaporation solutions that maximize heat transfer, minimize downtime, and reduce operational costs.

From design to commissioning, our FCE systems are backed by process expertise, manufacturing excellence, and global support - making SED a trusted partner for industrial concentration processes.

Frequently Asked Questions

Revolutionizing Tough-Process Evaporation

Experience the reliable, high-efficiency concentration with SED’s Forced Circulation Evaporator - engineered for durability, cost-effectiveness, and challenging applications.