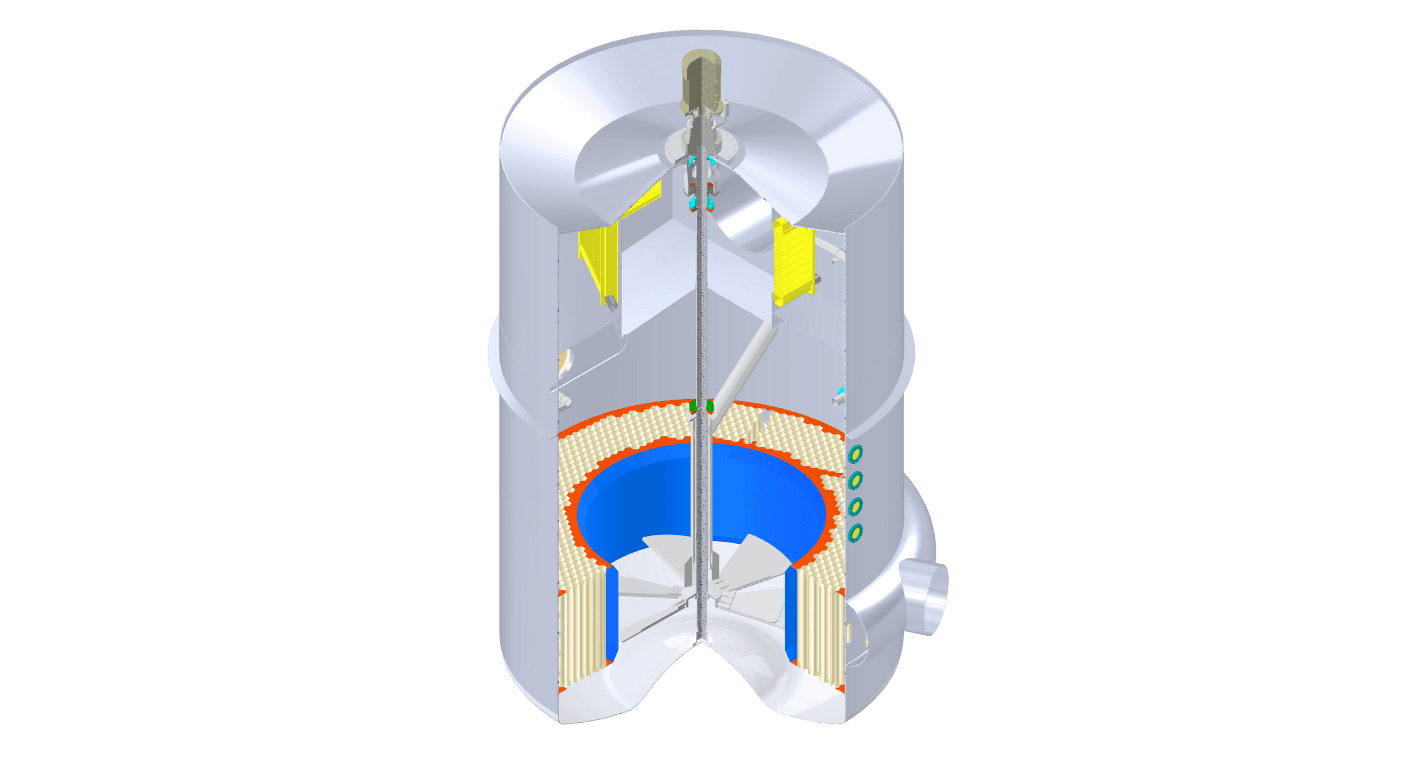

Batch Pan with Honeycomb Calandria

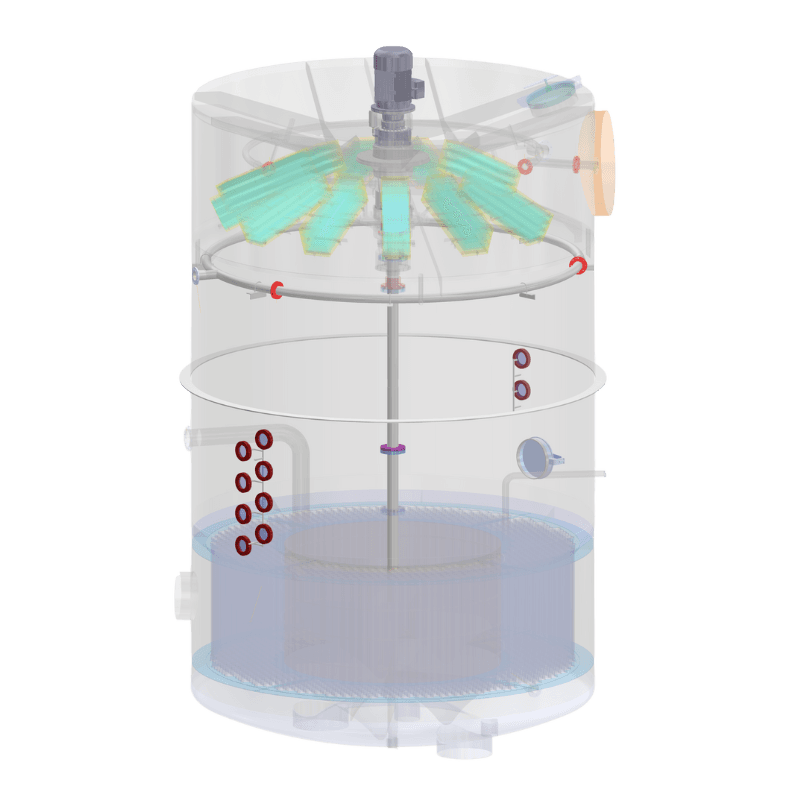

SED’s specially designed batch pan with honeycomb calandria features a bundle of tubes arranged in a honeycomb pattern without traditional top and bottom tube plates. A central downtake, equipped with SED’s uniquely designed six-blade mechanical circulator, boosts massecuite circulation for uniform crystal growth, higher exhaustion and higher heat transfer within the tubes.

How It Works

Heat Transfer

Massecuite Circulation

Evaporation and Crystallization

Batch Completion and Discharge

Why Is It Needed?

Improves sugar quality with uniform crystallization and better massecuite circulation.

Increases yield through higher exhaustion.

Efficient heat transfer and low ΔT operation significantly reduce energy consumption.

Handles all massecuite types while minimizing false grains and colour inclusion.

Compatible with low-temperature vapor, allowing seamless integration with MVR systems.

Fully automated system ensures easy operation and low maintenance.

Improves sugar quality with uniform crystallization and better massecuite circulation.

Handles all massecuite types while minimizing false grains and colour inclusion.

Increases yield through higher exhaustion.

Compatible with low-temperature vapor, allowing seamless integration with MVR systems.

Efficient heat transfer and low ΔT operation significantly reduce energy consumption.

Fully automated system ensures easy operation and low maintenance.

Salient Features

Enhanced heat transfer improves crystallization and enables reliable operation with low-temperature vapors, ensuring MVR compatibility.

Improved circulation and uniform saturation reduces conglomeration, prevents false grain formation, minimal colour inclusion and deliver higher massecuite quality.

Large downtake enables efficient circulation.

Reduced massecuite stagnation due to the absence of tube plates, leading to lower washing steam consumption and minimized sugar recirculation.

Optimized design enables integration of larger heating surfaces, allowing for higher-capacity pans within a reduced footprint.

Reduced diameter and prefabricated single piece calandria significantly lower transportation costs and minimizes installation time.

Efficient extraction of non-condensable gases (NCGs) enhances overall thermal performance, ensuring optimal steam utilization and reduced energy demand.

Superior material grades for calandria enhances equipment durability and extends service life.

Suitable for all types of massecuites (Refined, Raw, A, B and C).

Applications Across the Sugar Industry

SED’s Batch Pan delivers reliable performance across diverse sugar production setups:

Raw Sugar Mills

Refineries

Multi-Effect and MVR Integrated Plants.

Specialty Sugar Products

Why Partner with SED?

Innovation at SED goes beyond technology - it’s about creating value. Our Batch Pan systems combine patented designs, process expertise, and global support to deliver measurable gains in sugar yield, energy efficiency, and operational reliability. From engineering to commissioning, SED ensures your production standards are consistently exceeded.

Frequently Asked Questions

Revolutionizing Sugar Production. Redefining Standards.

Experience the next generation of sugar crystallization with SED’s Batch Pan with Honeycomb Calandria - engineered for high yield, energy efficiency, and superior product quality.