Maximize Extraction. Minimize Power Consumption.

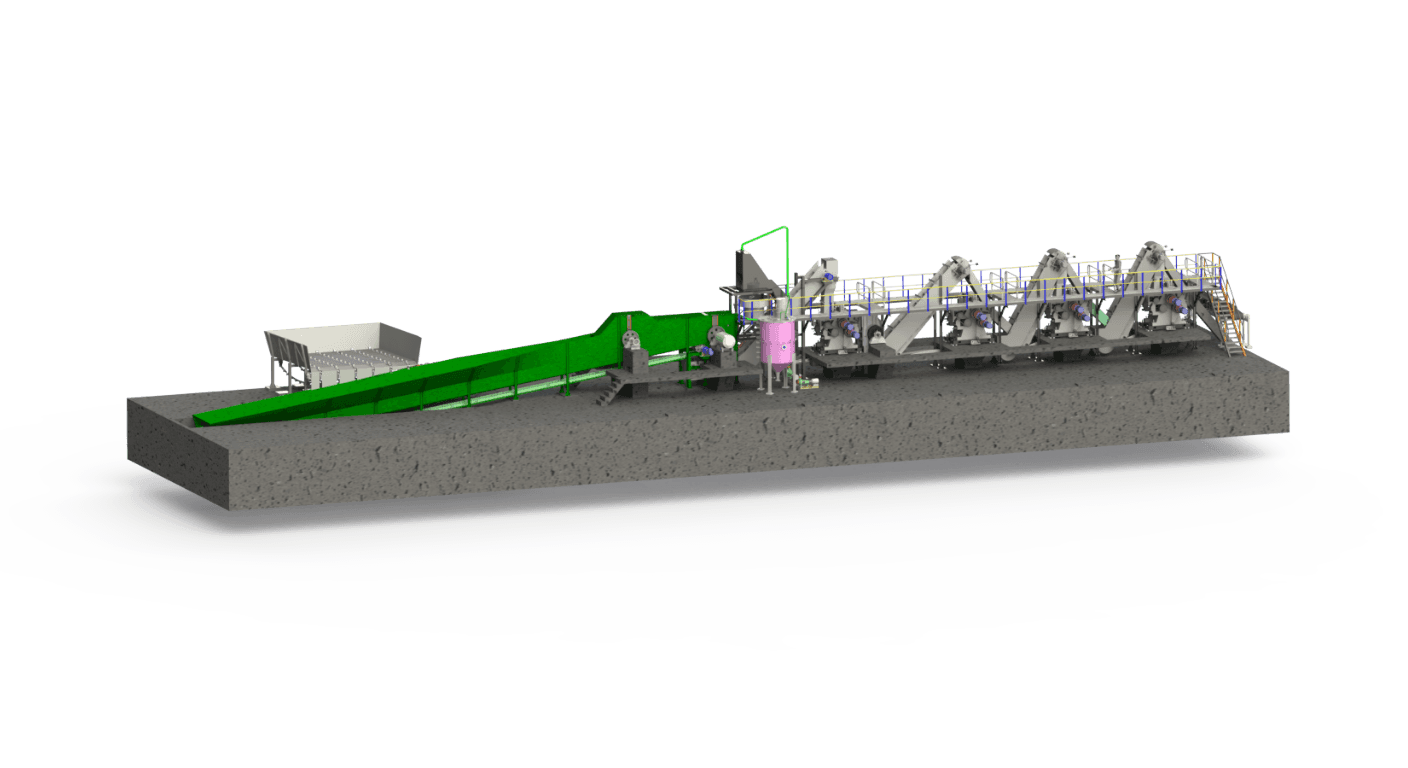

SED’s Milling Systems, also known as Milling Tandems, are precision-engineered units designed to extract maximum juice from prepared sugarcane with optimal energy efficiency. Featuring Three-Roller Mills with independently driven rollers, VFD-controlled motors, and integrated feeding mechanisms like the Toothed Underfeed Roller (TUFR), these systems ensure uniform load distribution, high juice recovery, and smooth bagasse handling.

Built for continuous operation and energy efficiency, SED Milling Systems combine automation, precision engineering, and robust construction to deliver consistent performance while reducing operational costs.

How It Works

Cane Preparation

Cane Distribution

Milling Process

Sequential Milling

Juice Collection

Bagasse Handling

Challenges with Conventional Mills

High power consumption.

Complex mechanical alignment.

Frequent downtime and skilled maintenance.

Bulky civil foundation requirements.

High power consumption.

Frequent downtime and skilled maintenance.

Complex mechanical alignment.

Bulky civil foundation requirements.

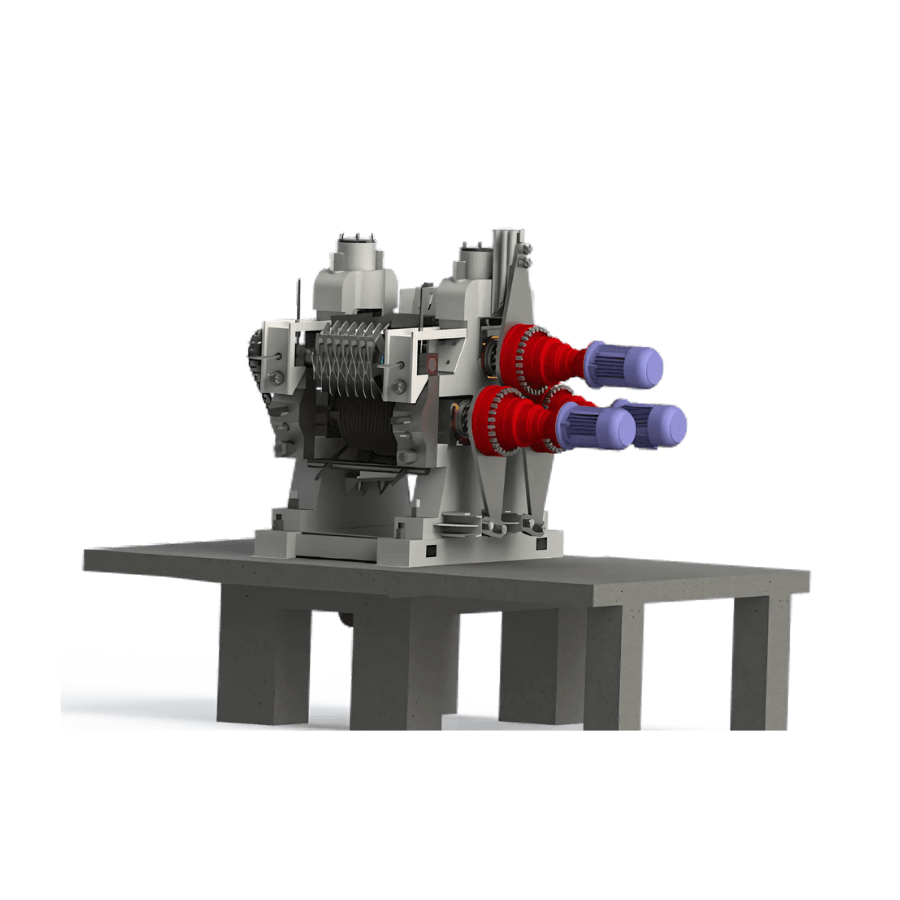

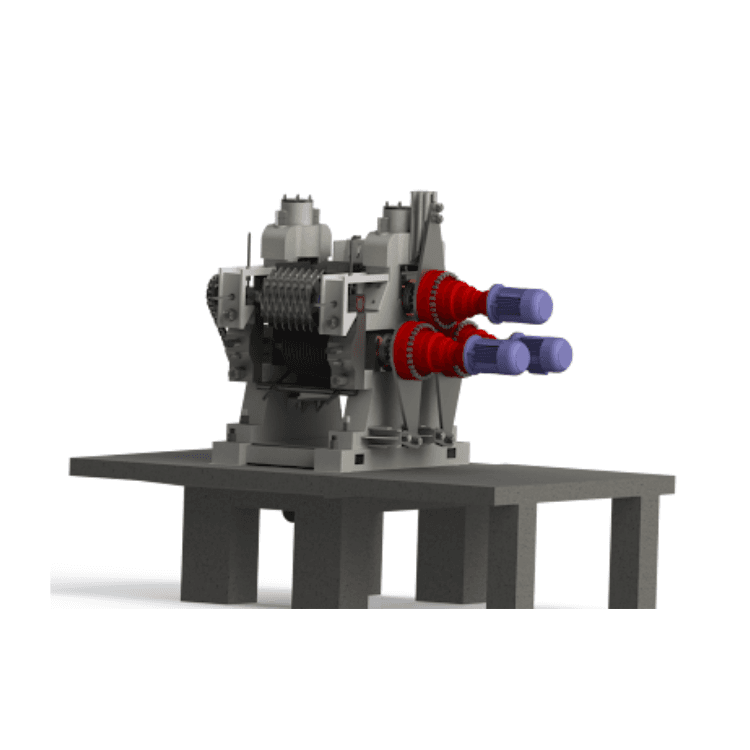

SED’s Mill Drive System Solution

Compact inline planetary drives.

Eliminates heavy foundations and civil structures.

Fewer components, spares, and lubrication points.

Full automation with low-speed operation (1–4 RPM).

Key Advantages

| Efficiency | Direct Benefit |

|---|---|

| >90% Gearbox Efficiency | Reduced power bills to 10 kW/Ton of cane |

| Variable Frequency Drives | Precision milling ensures maximum juice extraction |

| Low-Speed Operation (1–4 RPM) | Higher Primary & Reduced Mill Extraction (PME/RME) |

| Fewer Components & Maintenance Points | Lower downtime and OPEX |

| No Extra Foundation Needed | Saves civil costs and enables faster erection |

| Semi-Skilled Operation Feasible | Reduced manpower costs |

| Fully Automated Mode | Consistent performance with minimal supervision |

Salient features

Individually driven rollers for precise load control.

TUFR and Chevron grooved rollers for uniform cane feeding.

Integrated cutters and inter-rack conveyors for sequential milling.

Compact Mill Drive system eliminating bulky foundations.

Full automation with VFD-controlled motors for energy efficiency.

Reduced components and maintenance points for lower OPEX.

Applications Across the Sugar Industry

SED Milling Systems are widely used in:

Sugar Mills

Biofuel Plants

Process Industries

Why Partner with SED?

SED combines precision engineering, automation, and energy-efficient design to deliver milling systems that maximize juice extraction while minimizing power consumption and operational costs.

From plant design to commissioning, our solutions ensure reliable performance, faster ROI, and scalable operations across small to large-scale sugar factories.

Frequently Asked Questions

Revolutionizing Milling Efficiency. Redefining Standards.

Join hundreds of global sugar factories already maximizing yield and reducing costs with SED Milling Systems - engineered for high extraction, energy efficiency, and long-term reliability.