Turning Excellence into Tangible Outcomes

Real Results Delivered

From achieving 25% steam on cane in brownfield projects (2015–16) to delivering fully boiler-less plants (2019–20).

Repeat Business & Trust

More than 60% of our order book comes from repeat customers who have seen the tangible benefits of our technology firsthand.

Holistic Engineering

We look at the entire factory ecosystem. From sugarcane preparation to sugar bagging, we analyse energy balance, water balance, and equipment performance to ensure high efficiency across the system.

A History of "Firsts"

SED has consistently led the global sugar industry with groundbreaking innovations, introducing technologies that were implemented for the first time ever and reshaping what factories can achieve.

First Boiler-Less Sugarcane Processing Plant (Global)

First MVR Based Distillery (India)

First to Achieve 25% Steam on Cane in Greenfield Plants (Global)

First Low-Temperature Evaporator Module (LTEM®)

First Spray Continuous Pan (SCP®) in the Indian Market

First Brownfield Capacity Doubling Without New Boilers

Case Studies: Real Projects. Real Impact.

The Turnaround Story

Challenge: A financially distressed 2500 TCD plant with outdated infrastructure and high energy costs due to external fuel purchase.

Solution: Comprehensive technical audit and phased modernization plan focusing on energy reduction and process debottlenecking.

Result: Plant revived, stabilized, and became profitable on a sustainable basis.

Phases:

- Phase 1: Capacity expanded from 2500 TCD to 3600 TCD.

- Phase 2: Capacity further increased from 3600 TCD to 5000 TCD (achieving up to 5500 TCD).

- Achievement: Won the prestigious National Efficiency Award.

Key Takeaway: Achieved massive capacity jump without any investment in new steam generation section. Massive reduction in steam demand from 54% to 28% on cane.

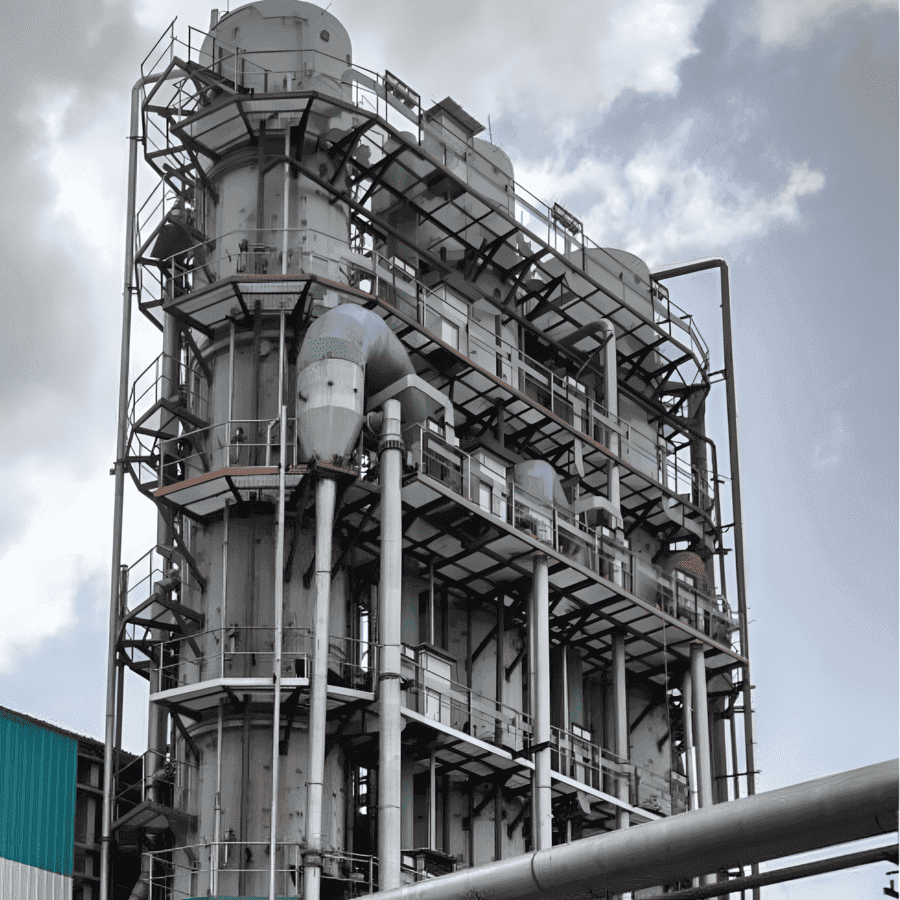

The Zero-Emission Revolution: Eco Tech Agro

Project: World's First Boiler-less Sugarcane Processing Plant

SED implemented its pioneering Boiler-Free Technology using Mechanical Vapour Recompression (MVR) based Low-Temperature Evaporation (LTE®). This 750 TCD sugarcane processing plant operates entirely without a boiler, utilizing electrical energy instead of thermal combustion.

Key Achievements:

- Zero Emissions: Complete elimination of smoke and ash; no CO2 emissions.

- 100% Bagasse Saved: Saved biomass is being directed to their existing paper plant.

- 100% Water Recovery: The plant requires no external water source and using 100% high-quality cooled condensate for irrigation.

- Energy Efficiency: Lower power consumption in its class through MVR closed-loop technology.

- Higher Yield: Improved reduced mill extraction more than 98% and bagasse moisture less than 45% ensures higher yield.

Powering the Giant: Al-Khaleej Sugar Refinery Dubai, UAE

Project: Falling Film Plate Evaporator Integrated with MVR for the World's Largest Standalone Sugar Refinery

Challenge: Processing massive volumes requires immense thermal energy, making efficiency a critical operational priority.

Solution: SED deployed its advanced Low Temperature Evaporator (LTE®) technology to operate in conjunction with Mechanical Vapor Recompressors (MVR).

Key Achievements:

- Massive Scale: Successful installation of world largest Falling Film Plate Evaporators (FFPE) with a total heating surface area of 34,000 m².

- Energy Optimization: Significant reduction in steam and power demand by recycling thermal energy through recompression, setting a benchmark for energy efficiency in mega-refineries.

Capacity Enhancement: Shri Dutt India, Kandla, Gujarat

Project: 2.5x Capacity Expansion via MVR based Crystalization

Challenge: The client required a massive expansion in refining capacity without a proportional increase in steam generation infrastructure or energy costs.

Solution: A strategic upgrade using Mechanical Vapour Recompressors (MVR) integrated with Honeycomb Calandria Batch Pans and Falling Film Plate Evaporators.

Key Achievements:

- 2.4x Capacity Jump: Production capacity increased from 1,000 TPD to 2,400 TPD (Refined Sugar Output).

- Steam Efficiency: Achieved a groundbreaking steam consumption rate of <0.40 Ton per ton of sugar (reduced from 1.0 Ton/ton).

- Technology Deployed: Installation of Direct Contact Heaters, Condensate Flashing Systems, melt concentration and sophisticated MVR based Batch Pan.

Our Equipment for Sugar Refineries

Awards &Recognition

Engineering Excellence for India’s Leading Companies

Partnering with Global Leaders Across Continents

Why Choose SED?

Expertise

Our team brings years of industry experience, ensuring high-quality solutions tailored to your needs.

Innovation

We remain at the forefront of innovation, continuously adopting advanced technologies to enhance efficiency and sustainability across sectors.

24 x 7 Support

From project inception to post-commissioning support, we are committed to our clients every step of the way.

Connect with us Today !

Fill up the form and our team will get back to you within 24 hours.

Let's Discuss Your Plant's Potential

Whether you're looking to slash your fuel bills, expand your capacity on a budget, or revive a dormant unit, our team of experts is ready to engineer a solution tailored to your needs.