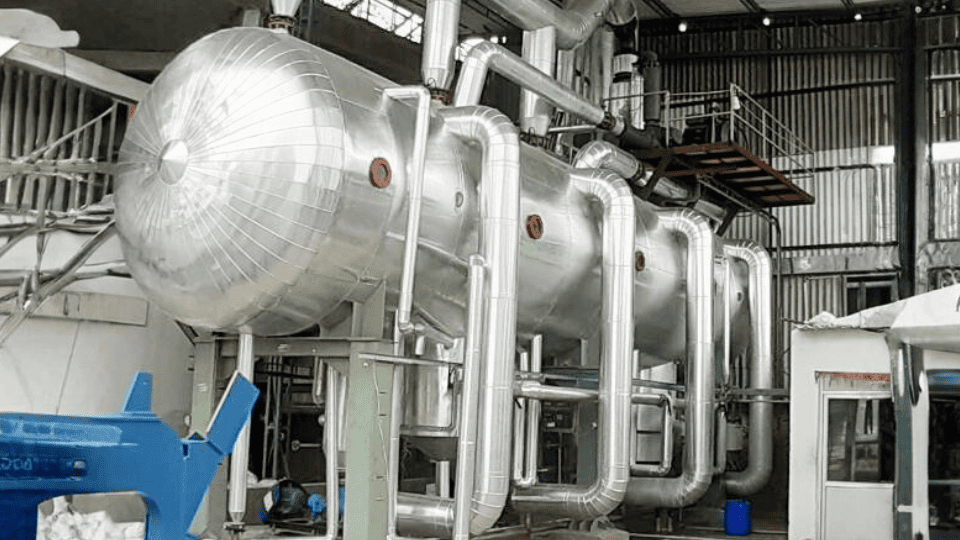

MVR-Based Low-Temperature Evaporator (LTE®)

SED’s patented MVR-based Low-Temperature Evaporator (LTE®) is an advanced plate-type falling film evaporator system that utilizes Mechanical Vapor Recompression (MVR) to treat wastewater or concentrate thermosensitive liquids at low temperatures (typically 40°C–65°C) under vacuum conditions. This highly energy-efficient technology is most effective for clean water recovery, achieving volume reduction, and often supporting zero-liquid-discharge (ZLD) processes making it a sustainable and environmentally responsible solution.

Working Principle

Feed Distribution

Heat Transfer

Evaporation Terminology

MVR (Mechanical Vapor Recompression)

Clean Water Recovery

Waste Heat Recovery

Why Choose MVR-based LTE®?

Highly Energy Efficient

MVR recycles vapor energy, requiring only 10–15 kWh per ton of water evaporated - far less than traditional multi-effect evaporators.

Boiler-less Operation

Ideal for industries without boilers, enabling simple and efficient wastewater treatment. Simplified infrastructure significantly reduces the space requirement, fuel storage, & water treatment systems for greenfield projects.

Sustainable & Environmental Compliance

MVR operation reduces greenhouse gas emissions by up to 90% compared to steam-driven systems, supporting sustainable water management and ZLD goals.

Compact Footprint

Achieves a large heating surface area within a minimal footprint, and is further scalable, reducing space and structural requirements for installation.

Automated Control

Advanced automation enables complete equipment control, preventive maintenance alarms, and enhanced safety measures, including CIP (Cleaning-In-Place), from the DCS (Distributed Control System) with no manual intervention.

Easy Installation

Easy transport and quick assembly with a compact, skid/self-supported design that requires minimal civil work, structure, and erection time.

24x7 Remote Operational Support

Continuous online monitoring, assistance, and control to ensure uninterrupted performance, quick troubleshooting, and optimal operation of equipment from anywhere.

Highly Cost Effective

Lowering operating cost (energy, consumables & maintenance) to less than $1 per ton of treated water.

High-Quality Distillate

Produces clean condensate (low TDS) for reuse, reducing freshwater demand and environmental impact.

Highly Energy Efficient

MVR recycles vapor energy, requiring only 10–15 kWh per ton of water evaporated - far less than traditional multi-effect evaporators.

Easy Installation

Easy transport and quick assembly with a compact, skid/self-supported design that requires minimal civil work, structure, and erection time.

Boiler-less Operation

Ideal for industries without boilers, enabling simple and efficient wastewater treatment. Simplified infrastructure significantly reduces the space requirement, fuel storage, & water treatment systems for greenfield projects.

24x7 Remote Operational Support

Continuous online monitoring, assistance, and control to ensure uninterrupted performance, quick troubleshooting, and optimal operation of equipment from anywhere.

Sustainable & Environmental Compliance

MVR operation reduces greenhouse gas emissions by up to 90% compared to steam-driven systems, supporting sustainable water management and ZLD goals.

Highly Cost Effective

Lowering operating cost (energy, consumables & maintenance) to less than $1 per ton of treated water.

Compact Footprint

Achieves a large heating surface area within a minimal footprint, and is further scalable, reducing space and structural requirements for installation.

High-Quality Distillate

Produces clean condensate (low TDS) for reuse, reducing freshwater demand and environmental impact.

Automated Control

Advanced automation enables complete equipment control, preventive maintenance alarms, and enhanced safety measures, including CIP (Cleaning-In-Place), from the DCS (Distributed Control System) with no manual intervention.

Salient features

Vacuum-enabled evaporation at 40°C–65°C minimizes corrosion, volatile emissions, and energy loss, ideal for wastewater and thermosensitive liquids.

Reduces wastewater volume by 80–95%, concentrating solids for easier disposal or recovery, supporting sustainable ZLD goals.

Plate design and turbulent flow handle high-TDS effluents with minimal downtime.

Modular systems fit various scales starting from 10 KLD and easily scalable to 10 MLD.

Automated CIP and advanced predictive maintenance ensure high uptime and operational reliability.

Variable-speed compressors and pumps provide a high turn-down ratio.

Flexibility to absorb shock loads occurring due to change in feed characteristics (pH, TDS, BOD, COD etc.).

Harnessing the Power of Vapor Compression

MVR technology compresses and recycles vapor within the system, reducing energy consumption while maintaining high water recovery rates.This makes LTE® not only cost-efficient but also sustainable, contributing to a greener industrial footprint.

Applications Across Industries

Textiles

Reduce wastewater and recycle clean water.

Pharmaceuticals & Chemicals:

Achieve ZLD and reduce operational costs.

Electroplating

Recover water from high-strength effluents.

Distilleries & Breweries

Treat spentwash and RO rejects efficiently.

Sugar & Jaggery Production

Boiler-free, zero-emission sugarcane processing.

Revolutionizing Water Recovery. Setting New Standards.

Join the sustainability movement. Optimize water usage, reduce costs, and contribute to a greener future with SED’s MVR-based LTE®.