Efficient. Compact. Engineered for Maximum Thermal Performance.

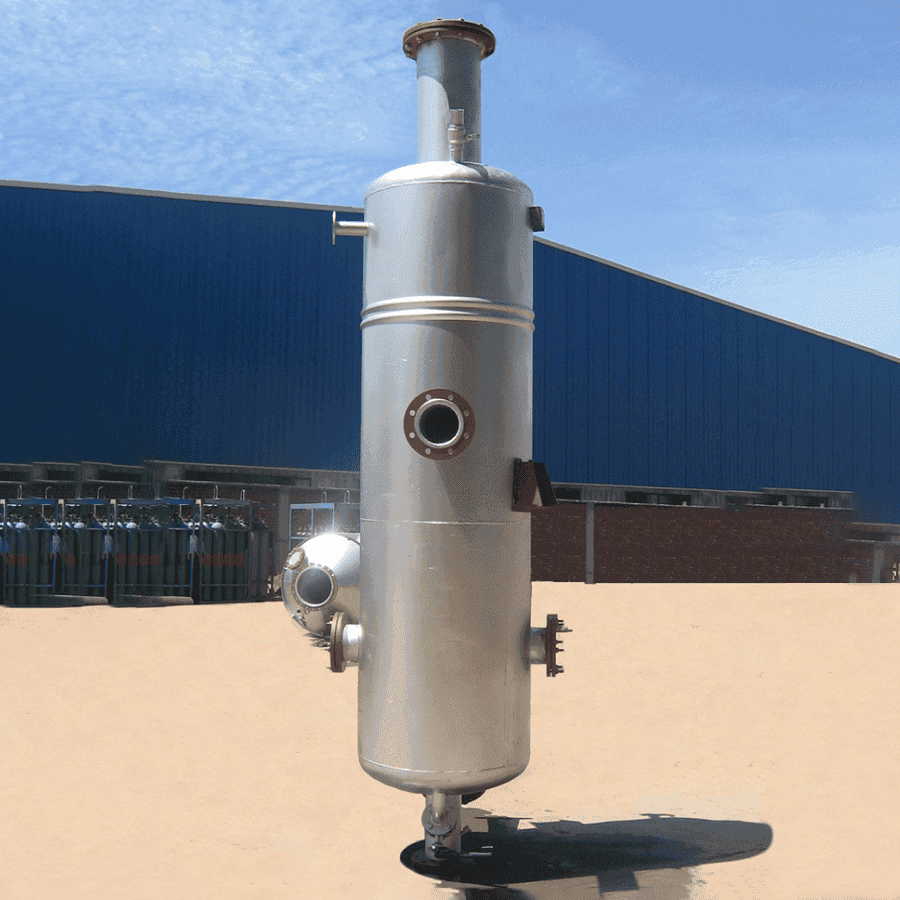

SED’s Direct Contact Heater (DCH) is designed to heat process fluids to nearly the same temperature as the heating vapor, achieving almost zero approach. By utilizing lower-grade heat and improving overall energy efficiency, DCH delivers superior heating performance with minimal maintenance. Its continuous operation, compact footprint, and high energy efficiency make it an ideal solution for modern sugar processing plants.

How It Works

Direct Contact Heating

Flow Guidance & Circulation

Non-Condensable Gas Removal

Contaminant Removal

Key Advantages

Minimal Temperature Approach

Achieves a temperature difference as low as 0–1°C between heating vapor and process fluid, resulting in higher final product temperatures.

Continuous Operation

Designed for uninterrupted operation without the need for frequent cleaning.

Reduced Retention Time

Minimizes sugar losses and improves overall process efficiency.

Zero Head Loss

Lowers pump power requirements, contributing to reduced energy consumption.

Low Maintenance

Minimal cleaning requirements ensure low operational costs and easy integration into sugar plant operations.

Minimal Temperature Approach

Achieves a temperature difference as low as 0–1°C between heating vapor and process fluid, resulting in higher final product temperatures.

Zero Head Loss

Lowers pump power requirements, contributing to reduced energy consumption.

Continuous Operation

Designed for uninterrupted operation without the need for frequent cleaning.

Low Maintenance

Minimal cleaning requirements ensure low operational costs and easy integration into sugar plant operations.

Reduced Retention Time

Minimizes sugar losses and improves overall process efficiency.

Salient features

Corrugated shell and rib-supported deflectors with inbuilt entrainment separator.

High turndown ratio for efficient operation between 30%–100% of design flow.

Lightweight structural layout with minimal floor space requirement.

Effective NCG removal via counter-flow design and ample vapor space.

Suitable for both pressurized and sub-atmospheric vapor conditions.

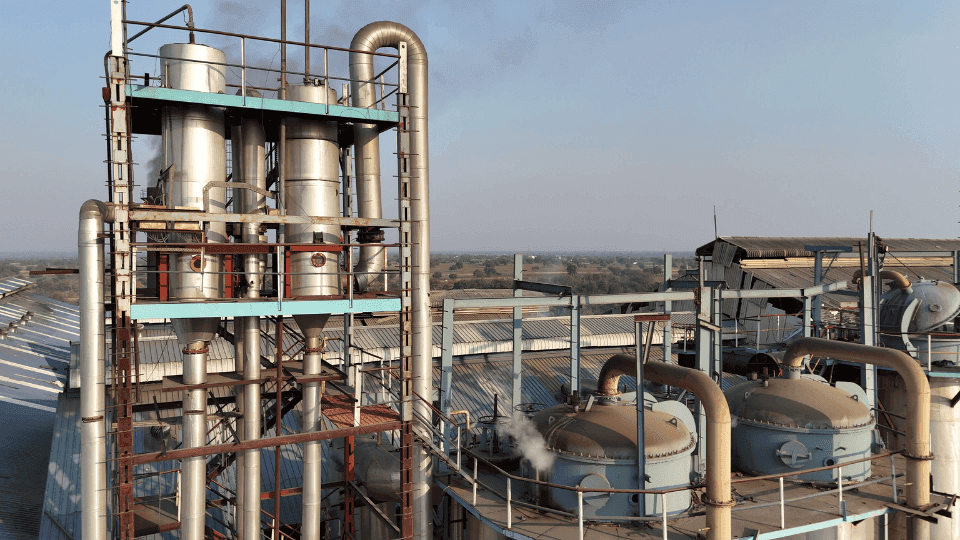

Applications Across the Sugar Industry

SED’s Direct Contact Heater is ideal for:

Raw Sugar Mills

Refineries

Multi-Effect Evaporation Systems

Large-Capacity Plants

Why Partner with SED?

SED’s DCH combines advanced thermal engineering, compact design, and energy-efficient operation to deliver measurable improvements in process efficiency and operational reliability. With real-world performance, continuous operation, and low maintenance, SED ensures your heat exchange processes are optimized for modern sugar production.

Frequently Asked Questions

Revolutionizing Heat Exchange. Setting New Standards.

Optimize thermal efficiency, reduce energy consumption, and ensure uninterrupted operation with SED’s Direct Contact Heater — engineered for compact design, continuous performance, and zero maintenance.