Efficient. Versatile. Engineered for Controlled Thermal Processing.

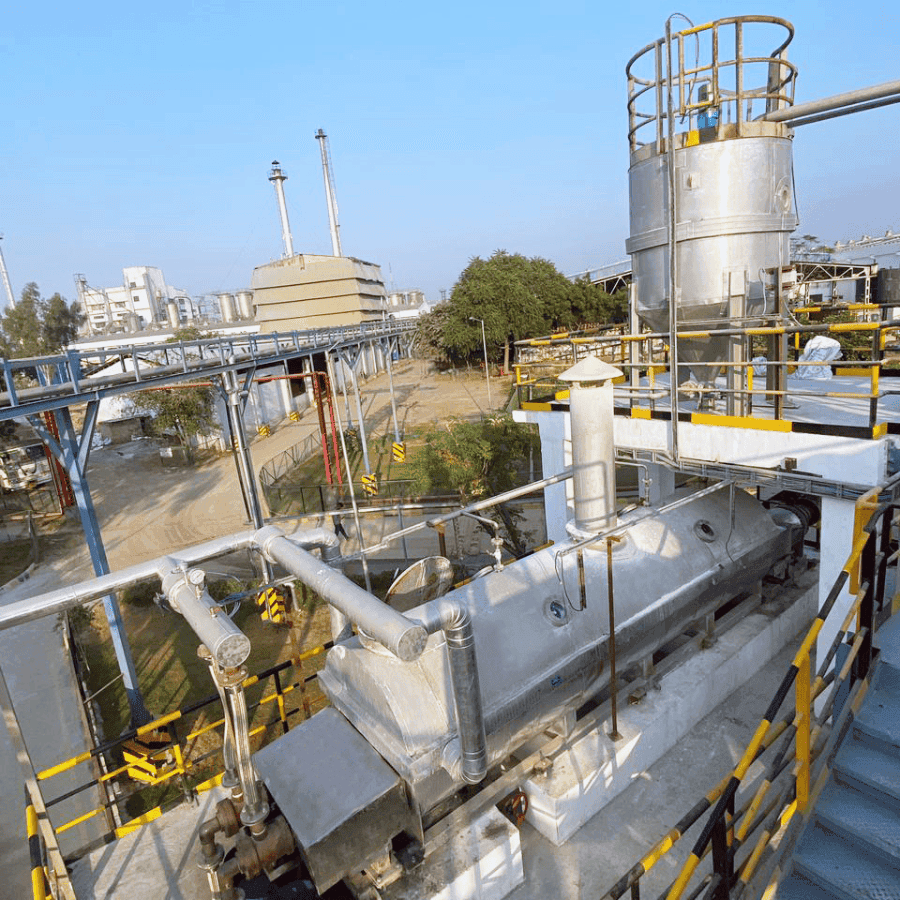

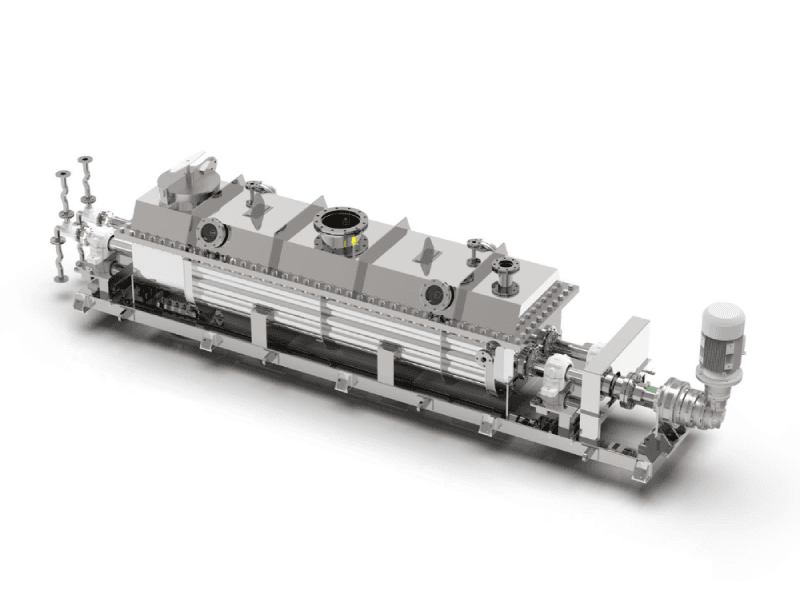

SED’s Paddle Dryer is a high-performance drying system designed for efficient thermal processing of pastes, powders, granules, and heat-sensitive materials. It supports a wide range of operations, including drying, cooling, crystallization, and solvent recovery. By circulating heating or cooling media through the drying chamber and hollow paddle discs, it ensures uniform thermal processing while maintaining product integrity.

With robust construction, dual rotating shafts, and integrated discharge and moisture removal systems, the Paddle Dryer is ideal for closed-loop, energy-efficient industrial operations.

How it Works

Indirect Heating & Media Circulation

Material Feeding & Agitation

Efficient Heat Transfer

Moisture Evaporation & Extraction

Continuous, Reliable Operation

Key Advantages

High Thermal Efficiency

Minimizes energy use while delivering consistent, controlled drying.

Compact & Closed-Loop Design

Large heat transfer area in a small footprint reduces heat loss and emissions.

Uniform Product Quality

Controlled agitation and heat distribution ensure low final moisture content and consistent results.

Versatility Across Materials & Industries

Suitable for powders, pastes, granules, and viscous materials in food, pharma, and chemical sectors.

High Thermal Efficiency

Minimizes energy use while delivering consistent, controlled drying.

Uniform Product Quality

Controlled agitation and heat distribution ensure low final moisture content and consistent results.

Compact & Closed-Loop Design

Large heat transfer area in a small footprint reduces heat loss and emissions.

Versatility Across Materials & Industries

Suitable for powders, pastes, granules, and viscous materials in food, pharma, and chemical sectors.

Salient features

Supports multiple heat transfer media: steam, water, or thermic fluid.

Achieves low final moisture content (as low as 10%).

Integrated dryer–cooler combination for space efficiency.

Low-speed operation with rugged construction and heavy-duty bearings.

Self-cleaning paddle design minimizes dusting and maintenance.

Easy access for servicing reduces downtime.

Compact footprint lowers civil and erection costs.

Applications Across Industries

SED’s Paddle Dryer is ideal for:

Food Processing

Pharmaceuticals

Chemicals

High-Throughput Plants

Why Partner with SED?

SED combines advanced thermal engineering, innovative paddle design, and process expertise to deliver reliable, energy-efficient drying solutions. The Paddle Dryer ensures consistent product quality, optimal energy use, and sustainable operation for modern industrial applications.

Frequently Asked Questions

Revolutionizing Drying. Setting New Standards.

Boost operational efficiency, ensure uniform drying, and maximize energy savings with SED’s Paddle Dryer - engineered for versatility, reliability, and sustainable industrial performance.