Natural. Efficient. Engineered for Sustainable Thermal Management.

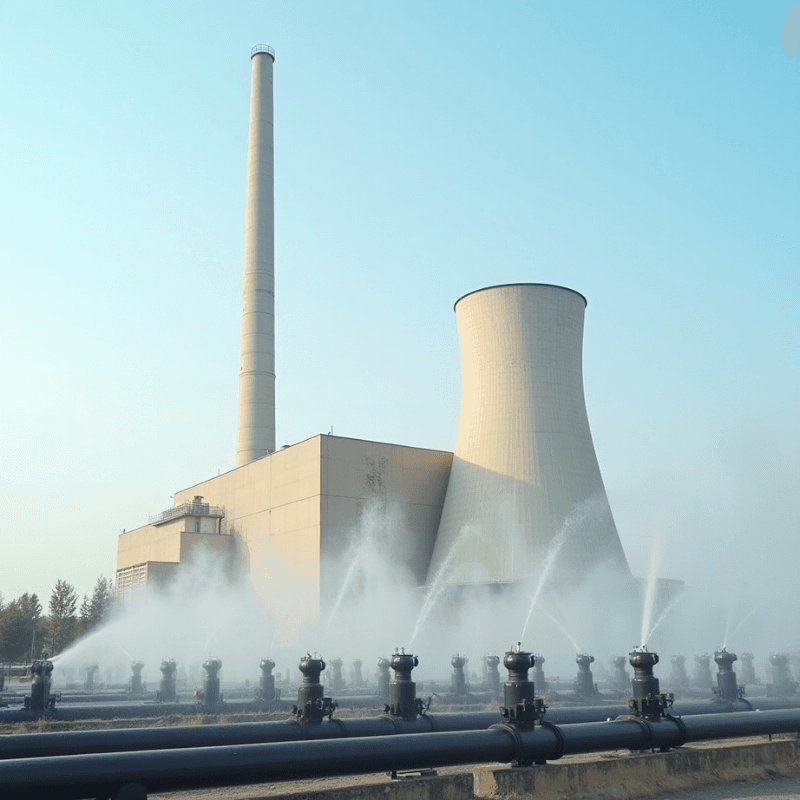

SED’s Spray Pond System is an advanced open-air cooling solution designed to efficiently lower process water temperatures through natural evaporation. By integrating modern materials, optimized nozzle design, and aerodynamic pond architecture, SED has redefined this century-old technology for today’s energy-conscious industries.

With over 200 systems successfully installed worldwide, SED’s spray ponds deliver reliable, low-cost, and environmentally friendly cooling - ideal for plants with open space availability or where mechanical cooling systems may not be feasible.

How It Works

Water Spraying

Evaporative Cooling

Heat Removal

Water Collection & Reuse

Energy Efficiency

Key Advantages

Energy-Efficient Cooling

Operates purely on natural convection, eliminating fan power and reducing overall energy costs.

Low Civil & Installation Cost

Simple construction with minimal infrastructure requirements makes it cost-effective to build and maintain.

Reliable and Low Maintenance

Optimized nozzles ensure clog-free operation and uniform spray distribution for consistent performance.

Water Conservation Design

Engineered for minimal drift losses and reduced evaporation beyond the pond area.

Scalable and Flexible

Adjustable spray flow rates accommodate variable cooling demands across different process loads.

Energy-Efficient Cooling

Operates purely on natural convection, eliminating fan power and reducing overall energy costs.

Water Conservation Design

Engineered for minimal drift losses and reduced evaporation beyond the pond area.

Low Civil & Installation Cost

Simple construction with minimal infrastructure requirements makes it cost-effective to build and maintain.

Scalable and Flexible

Adjustable spray flow rates accommodate variable cooling demands across different process loads.

Reliable and Low Maintenance

Optimized nozzles ensure clog-free operation and uniform spray distribution for consistent performance.

Salient features

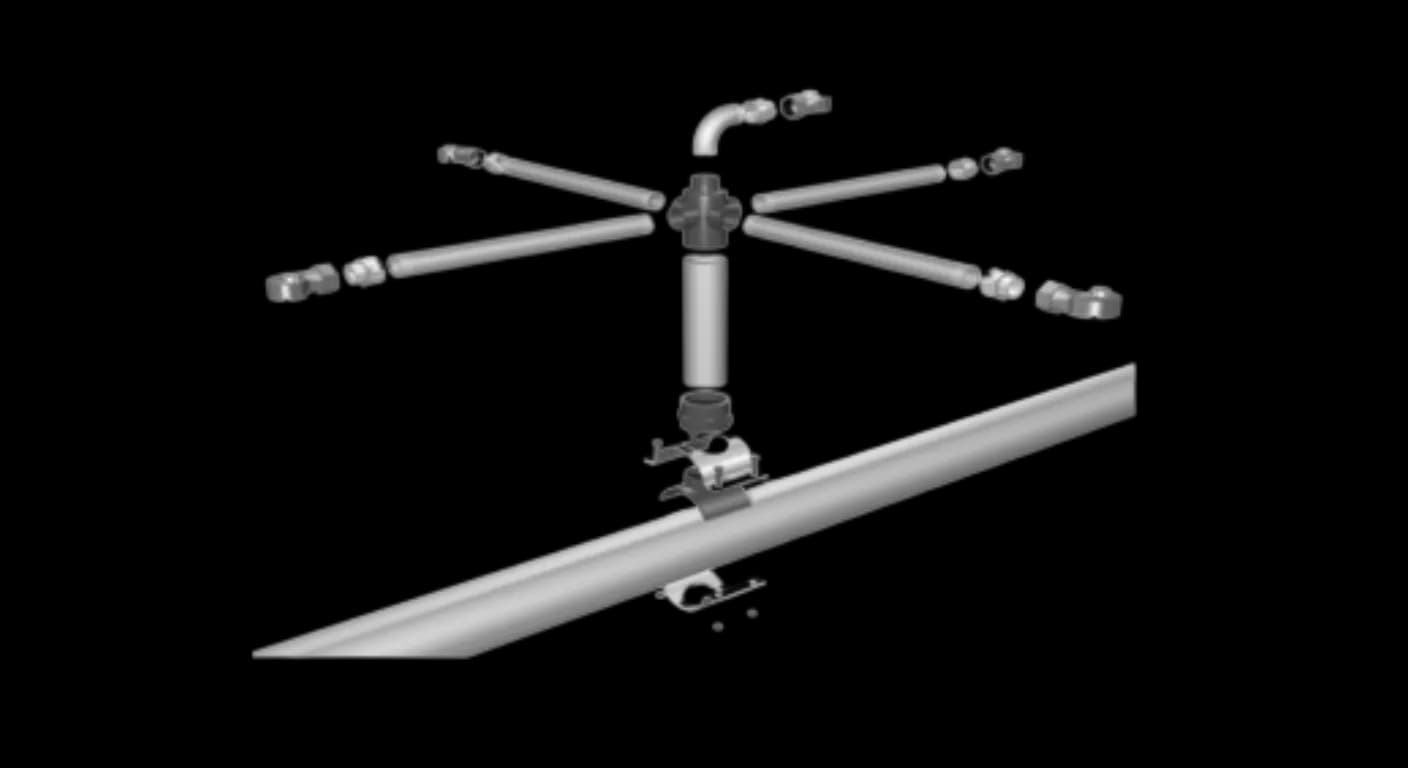

Advanced anti-choke spray nozzles for uniform droplet formation.

Aerodynamically designed pond geometry enhancing natural draft cooling.

Variable flow control for adaptive cooling performance.

Low drift design minimizing water loss and environmental impact.

Durable construction using corrosion-resistant materials for long service life.

Easy integration with condenser and process cooling circuits.

Applications Across Industry

SED’s Spray Pond systems are widely deployed in sectors requiring large-volume, cost-efficient cooling:

Sugar & Distilleries

Power Plants

Chemical & Fertilizer Plants

Paper & Pulp Processing

Textile & Dye Manufacturing

Why Partner with SED?

At SED, we bring deep engineering expertise, precision manufacturing, and full EPC integration to every cooling system we design.

From conceptual design to commissioning, our team ensures that your spray pond operates at maximum efficiency, reliability, and sustainability. We focus on reducing your energy footprint while maintaining consistent cooling performance, even under varying ambient conditions.

Our Capabilities Include:

- Process & Thermal Design Optimization

- Custom Fabrication and Field Installation

- Automation & Flow Control Integration

- Turnkey EPC Execution & Project Support

With SED, you gain more than a cooling system — you gain a partner in energy efficiency and environmental responsibility.

Frequently Asked Questions

Revolutionizing Efficiency. Redefining Cooling.

Experience sustainable, low-energy process cooling with SED’s Spray Pond System - where innovation meets simplicity for efficient, long-lasting thermal management.