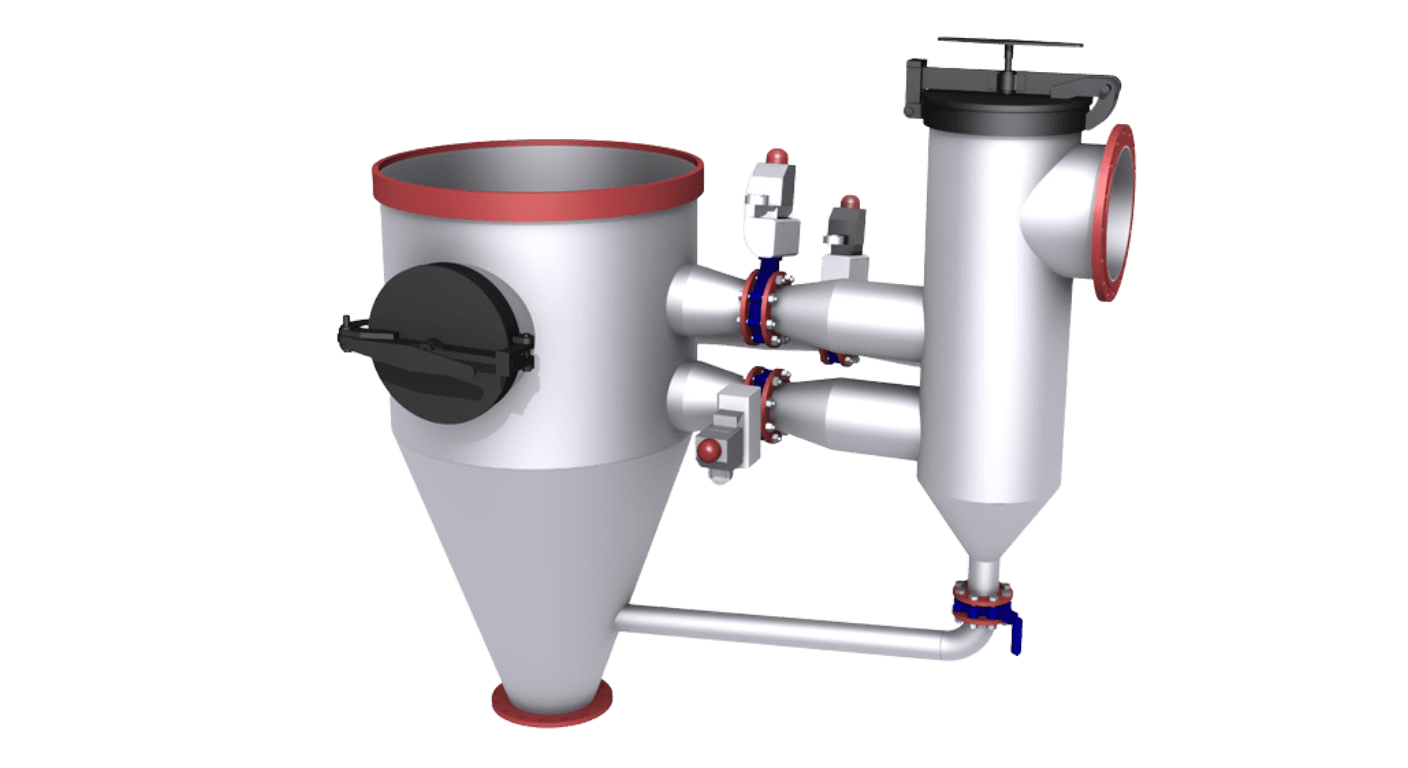

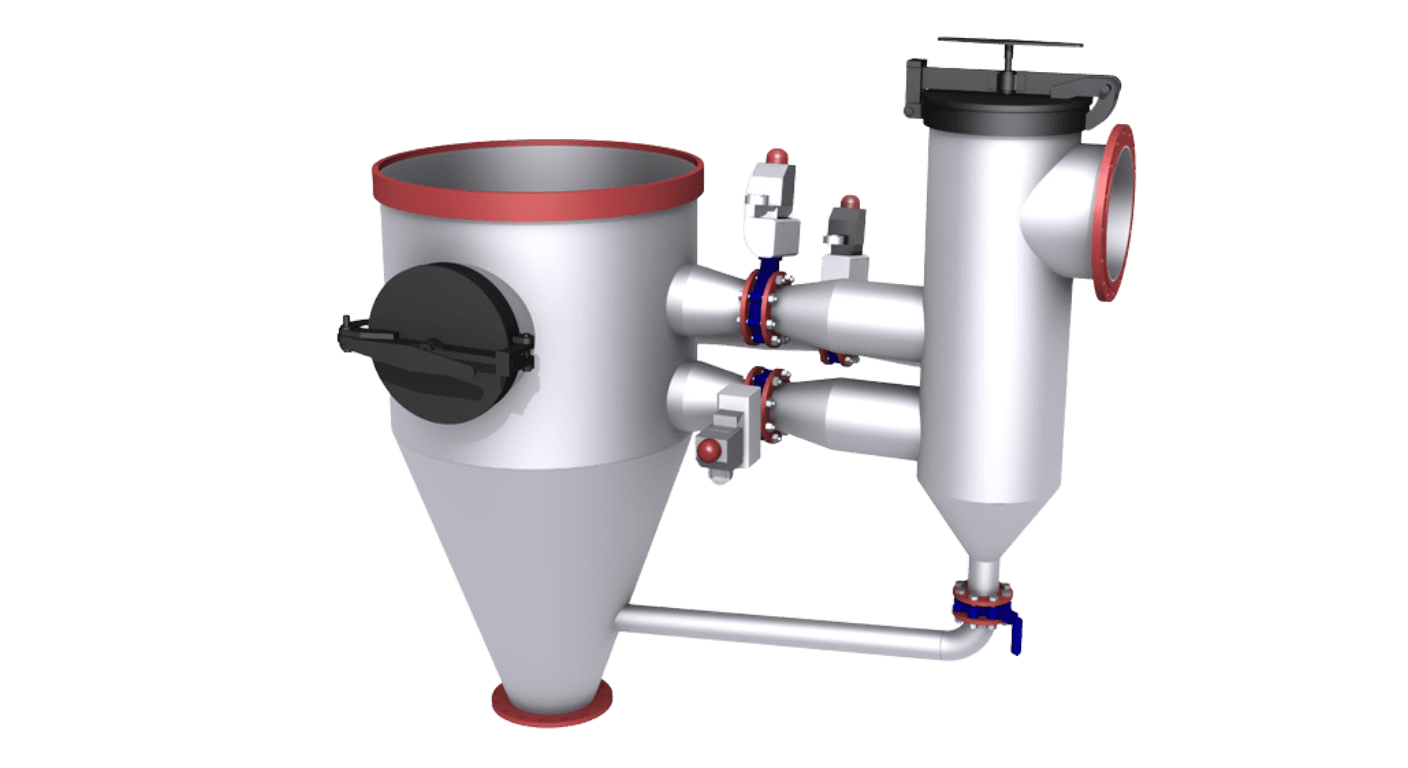

Multijet Condenser

SED’s multijet condenser is a specialized direct-contact heat exchanger designed for vapor condensation and quick vacuum creation in equipment such as pans and evaporators. It’s a unique combination of SED’s patented spray and jet nozzles ensures rapid condensation and NCG (Non-Condensable Gases) removal with minimal cooling water usage.

Working Principle

Vapor Inpu

Cooling Water Spray

Direct-Contact Condensation

Hot Water Collection

Vacuum Maintenance

Why it’s needed?

Minimized Pressure losses due to co-current operation.

Compact Size with ease of operation & maintenance.

Water jets emerging from the jet nozzles diminish the requirement of a vacuum pump.

Consistent vacuum reduces boiling time resulting enhanced steam economy

Low water & power consumption

Long life with use of corrosion resistant materials.

Outlet water can be fed through gravity to the cooling system.

Minimized Pressure losses due to co-current operation.

Low water & power consumption

Compact Size with ease of operation & maintenance.

Long life with use of corrosion resistant materials.

Water jets emerging from the jet nozzles diminish the requirement of a vacuum pump.

Outlet water can be fed through gravity to the cooling system.

Consistent vacuum reduces boiling time resulting enhanced steam economy

Salient features

Single Entry Multi jet Multi spray Condenser.

Hydro-dynamically designed nozzles creating strong turbulence.

Hand Operated Hinge Type SS Strainer with online cleaning operation to prevent clogging of jet & spray nozzles.

Man hole provided with a hinged door for easy & fast operation.

Innovative Automation System

Operates on pneumatic pressure - no high-pressure water required.

No actuator clogging, solenoid valve jamming, or internal tubing maintenance.

Externally visible nozzles allow real-time monitoring and troubleshooting.

Supports individual nozzle group control for performance fine-tuning.

Fully retrofit-compatible with existing systems using current PLCs and controllers.

Resistant to high-TDS water, preventing scaling, fouling, or actuator failure.

Energy Efficiency & ROI

Low Power Consumption

Higher Thermal Efficiency

Better ROI

Proven Reliability

Trusted by industry leaders including Balrampur Group, Triveni Group, Dhampur Group, EID Parry, NSL, Dhanalakshmi, and Jay Mahesh.

Applications Across Industries

SED’s Spray Condenser is ideal for industries requiring vacuum generation and efficient vapor condensation:

Sugar Industry

Distillery

Power Plants

Chemical & Fertilizer Plants

Paper & Pulp Industry

Why Partner with SED?

With decades of engineering expertise, Spray Engineering Devices (SED) combines process innovation, manufacturing precision, and automation intelligence to deliver the most advanced spray condenser solutions globally.

Our Expertise Includes:

- End-to-end design and thermal modeling.

- Custom manufacturing & modular installation.

- PLC/SCADA-based automation integration.

- After-sales service, maintenance & retrofitting support.

Frequently Asked Questions

Revolutionizing Efficiency. Setting New Standards.

Step into the future of condensation and vacuum generation with SED’s Spray Condenser System - where innovative fluid dynamics meet sustainable process efficiency.