Pharmaceutical

Produces a large amount of wastewater during drug manufacturing, chemical synthesis, and fermentation. This wastewater contains organic compounds, high TDS, solvents, and pharmaceutical residues, making treatment a big challenge. SED offers a simple and effective solution with our MVR-based Low-Temperature Evaporation (LTE®) system. Our technology provides a direct, chemical-free process that recovers clean water with low TDS. With a compact, automated, and energy-efficient design, we help pharmaceutical industries achieve Zero Liquid Discharge (ZLD) while reducing environmental impact and meeting regulations.

Challenges in Pharmaceutical Industry Effluent

High Organic Content

Wastewater contains pharmaceutical residues, solvents, and chemicals that can harm water bodies if untreated.

Complex Chemical Composition

Antibiotics, hormones, and other substances make conventional treatment difficult.

High TDS and COD Levels

The presence of dissolved solids and organic matter makes disposal challenging.

Toxicity & Antibiotic Resistance

If discharged untreated, wastewater can harm aquatic life and lead to antibiotic resistance.

Strict Regulations

Industries must follow strict environmental laws, making ZLD an important solution.

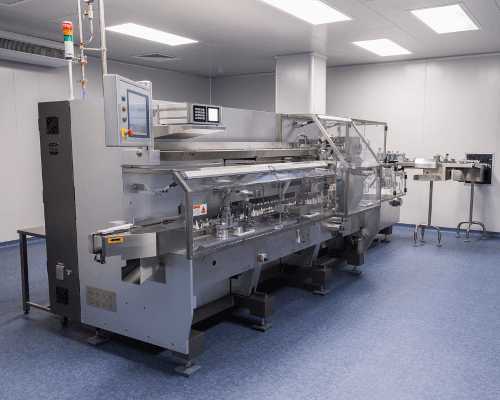

Our ZLD Solution for Pharmaceutical Wastewater

Treats all types of pharmaceutical wastewater, including solvent-based, high-TDS, and API-laden streams.

Recovers clean water with low TDS, making it reusable in production.

Minimizes waste volume, reducing disposal costs and environmental impact.

Is fully automated with PLC & VFD controls, enabling easy monitoring and troubleshooting.

Can be customized (vertical & horizontal evaporators) to fit different plant layouts with minimal space requirements.

Key Benefits of Our ZLD System

No Chemical Use

Unlike traditional methods, our process does not require chemicals.

Low Energy Consumption

MVR technology reduces power use, making treatment cost-effective.

Regulatory Compliance

Our system helps meet environmental laws for wastewater management.

Compact & Scalable Design

We customize ZLD systems to fit pharmaceutical plants of all sizes.

High-Quality Water Recovery

Recovered water can be reused, reducing the need for fresh water.

Chemical Recovery

Our process ensures valuable chemicals are recovered from effluents, adding extra value to the treatment process.