Efficient. Reliable. Engineered for Superior Fluid Circulation.

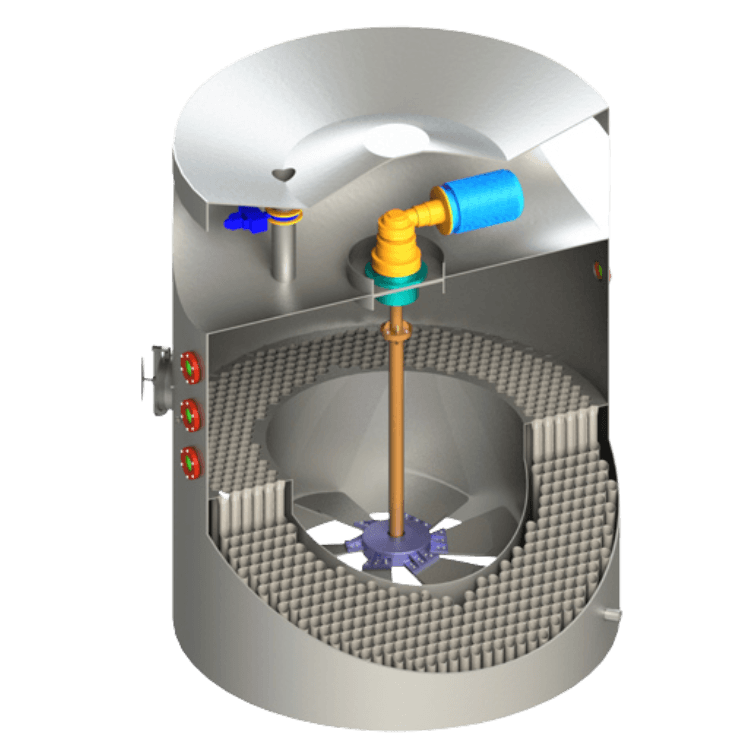

SED’s Mechanical Circulator (Agitator) is designed for highly viscous solutions, handling liquid-liquid or liquid-solid mixing with precision. Featuring hydrofoil blade design and robust stainless-steel construction, it generates effective vertical circulation with low power consumption. Equipped with a heavy-duty planetary gearbox and superior mechanical sealing, the circulator ensures continuous, reliable operation - ideal for critical processes like sugar crystallization in vacuum pans.

By providing precise control over fluid movement, the Mechanical Circulator improves product quality, enhances yield, and reduces energy consumption in industrial sugar operations.

How it Works

Motor-Driven Agitation

Vertical Circulation Loop

Turbulent Mixing for Homogeneity

Variable Speed Control

Reliable Sealing

Key Advantages

Massecuite Circulation

Ensures maximum throughput and uniform conditions inside vacuum pans for high-quality crystallization.

Improved Crystal Quality & Reduced Buildup

Prevents dead zones, leading to better crystal size distribution and reduced boiling times.

Increased Recovery

Enhances sugar crystal yield while maintaining molasses purity.

Low ΔT Operation

Supports reduced temperature difference operation, improving energy efficiency and product quality.

Massecuite Circulation

Ensures maximum throughput and uniform conditions inside vacuum pans for high-quality crystallization.

Increased Recovery

Enhances sugar crystal yield while maintaining molasses purity.

Improved Crystal Quality & Reduced Buildup

Prevents dead zones, leading to better crystal size distribution and reduced boiling times.

Low ΔT Operation

Supports reduced temperature difference operation, improving energy efficiency and product quality.

Salient features

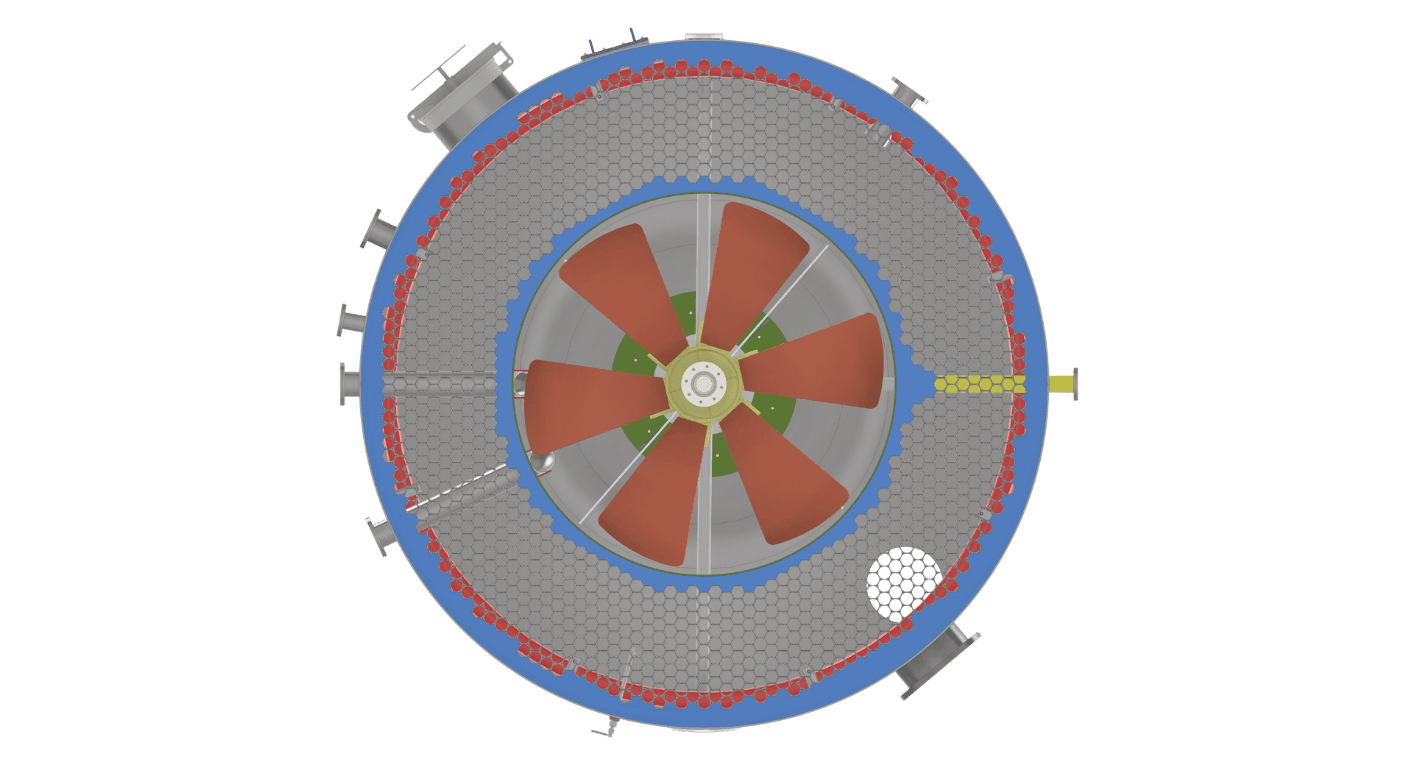

Superior stainless-steel construction and hydrofoil blade design for long-lasting performance.

Six hydrofoil blades provide efficient fluid circulation and high head.

Variable speed drive for operational flexibility.

Heavy-duty planetary gearbox and mechanical sealing for enhanced reliability.

Robust blade-shaft joint ensures stable, effective agitation.

Applications Across the Sugar Industry

SED’s Mechanical Circulator is ideal for:

Vacuum Pans

Molasses Processing

Multi-Effect Evaporation Systems

High-Capacity Sugar Plants

Why Partner with SED?

SED combines advanced hydrofoil blade technology, robust construction, and process expertise to deliver improved fluid circulation, enhanced product quality, and operational reliability. The Mechanical Circulator ensures energy-efficient, continuous, and precise mixing for modern sugar processing environments.

Frequently Asked Questions

Revolutionizing Fluid Circulation. Setting New Standards.

Enhance circulation efficiency, ensure uniform heat distribution, and maximize yield with SED’s Mechanical Circulator - engineered for high performance, durability, and operational reliability.