Efficient. Sustainable. Engineered for Maximum Thermal Recovery.

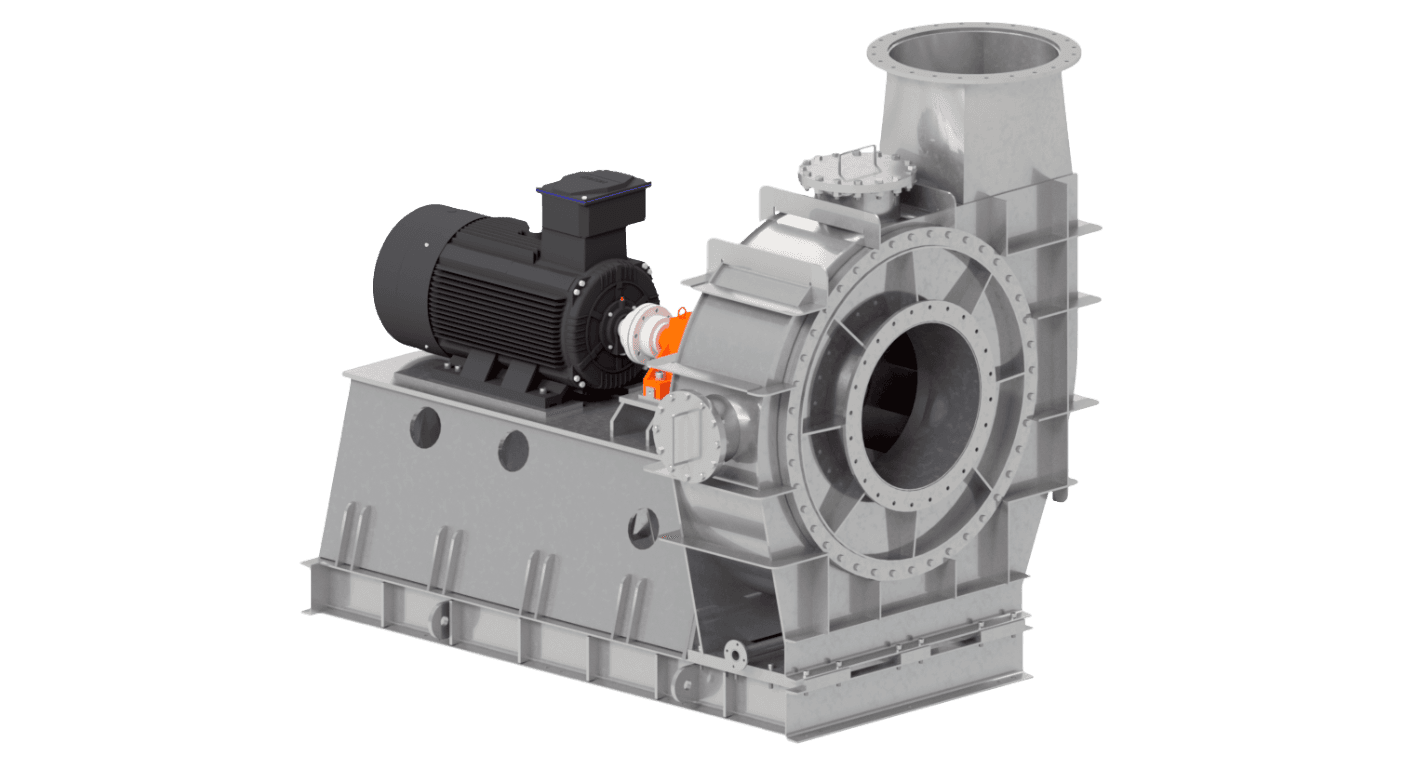

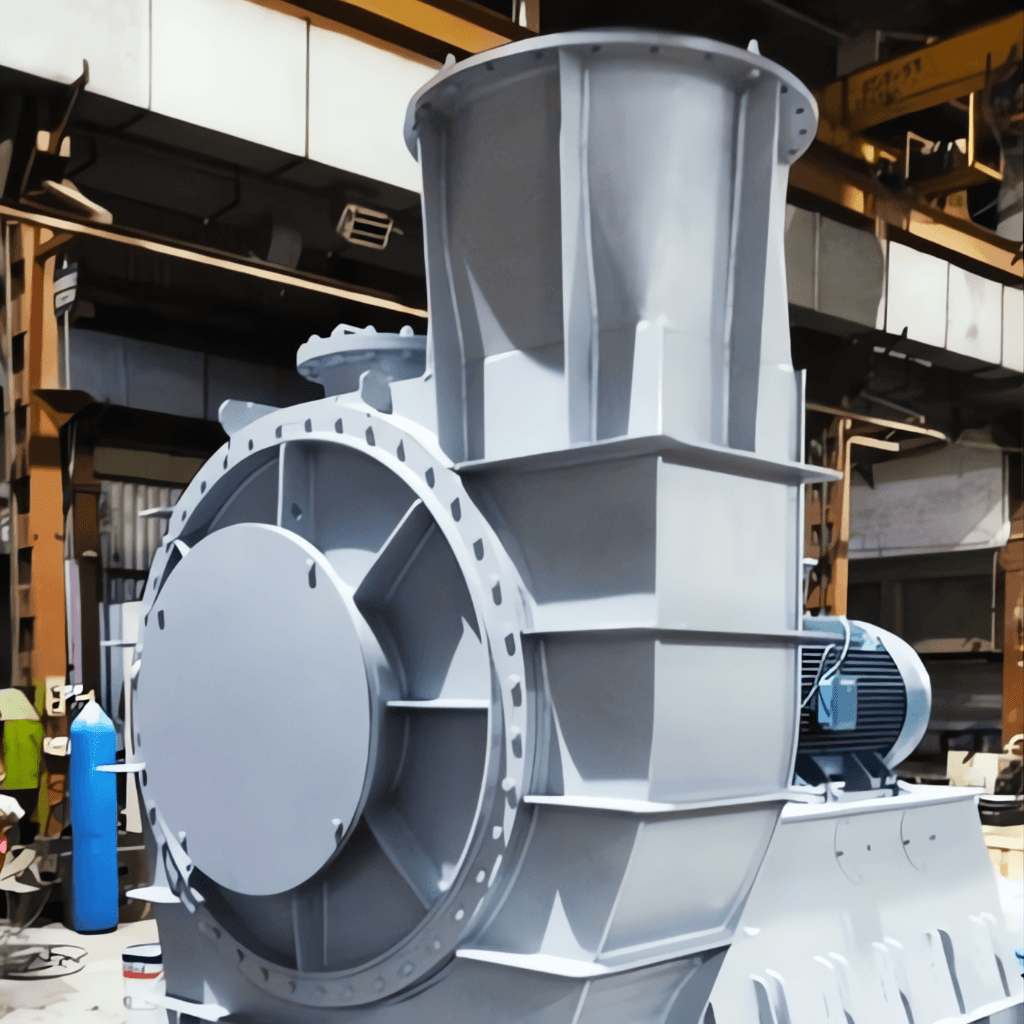

SED’s high-efficiency Mechanical Vapor Recompression (MVR) system, the EffiFlow Turbo Fan, is designed to dramatically reduce energy consumption and operational costs in industrial evaporation, distillation, and drying processes. By capturing low-pressure vapor, compressing it, and reusing its thermal energy, the fan minimizes the need for external steam, delivering significant cost savings and improving process efficiency.

Optimized for systems such as Low Temperature Evaporators (LTE®) and Plate Type Falling Film Evaporators, the EffiFlow Turbo Fan enhances evaporation rates, improves product quality, and supports higher throughput-making it a critical component in sustainable industrial operations.

How it Works

Evaporation and Vapor Capture

Vapor Compression

Thermal Energy Reuse

Latent Heat Recycling

System Efficiency and Stability

Energy and Resource Optimization

Key Advantages

Optimal Aerodynamic Performance

Backward-inclined, full-length radial blades ensure high efficiency and consistent airflow.

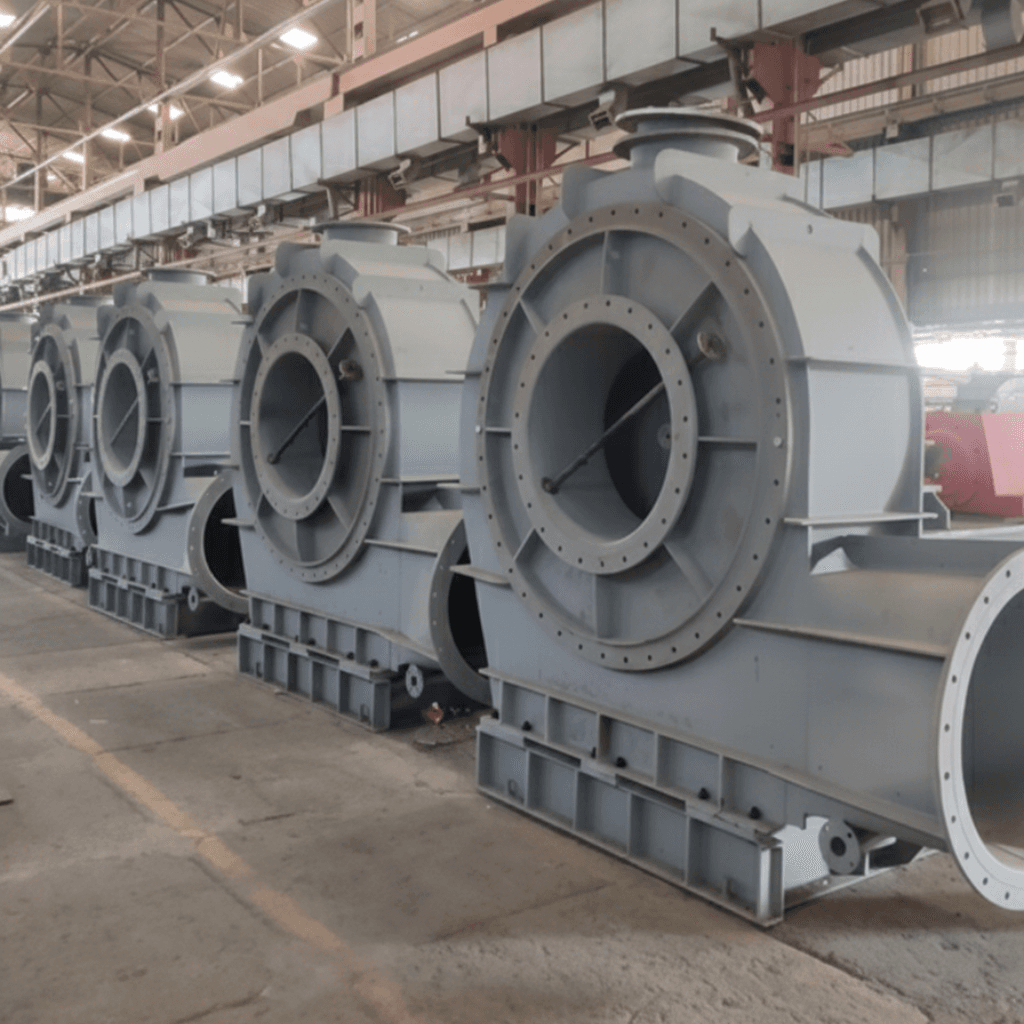

Durable Construction

Robust design guarantees reliable operation under demanding industrial conditions.

Vacuum-Compatible Operation

Gas-tight casing prevents leaks and contamination, enabling safe operation under vacuum.

Extended Service Life

Closed-face impeller with reinforced inlet geometry enhances performance and reduces wear.

Optimal Aerodynamic Performance

Backward-inclined, full-length radial blades ensure high efficiency and consistent airflow.

Vacuum-Compatible Operation

Gas-tight casing prevents leaks and contamination, enabling safe operation under vacuum.

Durable Construction

Robust design guarantees reliable operation under demanding industrial conditions.

Extended Service Life

Closed-face impeller with reinforced inlet geometry enhances performance and reduces wear.

SalientFeatures

Impellers and casings fabricated from ductile alloy plates for superior strength and durability.

Non-alloy structural steel pedestal providing a stable, vibration-free foundation.

Bearing housing with forced lubrication system for smooth, low-maintenance operation.

Applications Across Industries

The EffiFlow Turbo Fan is ideal for:

Why Partner with SED?

SED combines advanced MVR technology, aerodynamic design, and engineering expertise to deliver measurable gains in energy efficiency, product quality, and operational reliability. The EffiFlow Turbo Fan ensures sustainable, cost-effective, and high-performance operation for modern industrial evaporation and drying processes.

Frequently Asked Questions

Revolutionizing Efficiency,Setting New Standards

Maximize thermal efficiency, reduce steam consumption, and improve process sustainability with SED’s EffiFlow Turbo Fan - engineered for high performance, long-term reliability, and cost-effective energy recovery.