Efficient. Compact. Engineered for Superior Molasses Processing

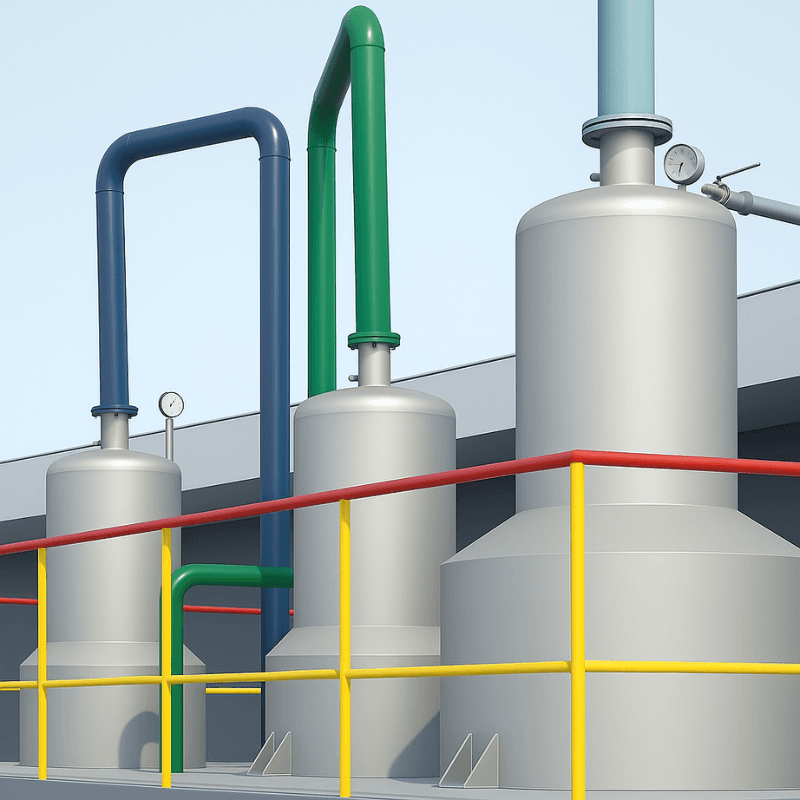

SED’s Molasses Conditioner is an innovative direct-contact device designed to dissolve sugar crystals in molasses efficiently - without adding water. By utilizing heat from non-condensable gases (NCGs) or low-pressure vapors, it delivers significant steam and power savings. The compact design features a static mixer, eliminating mechanical stirring and reducing maintenance requirements.

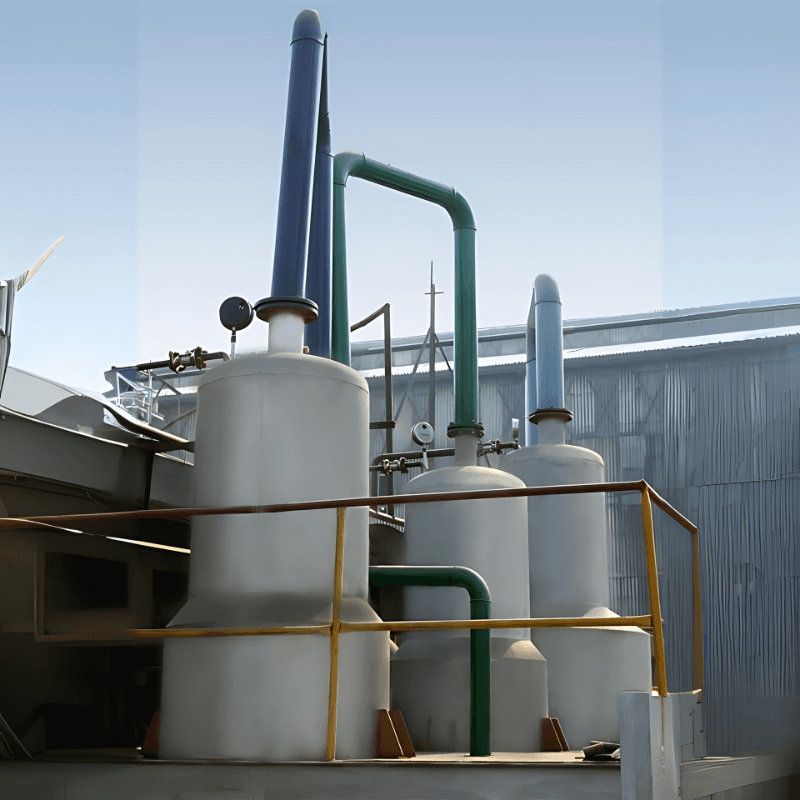

Ideal for modern sugar plants, the Molasses Conditioner ensures consistent product quality, energy efficiency, and smooth integration into existing process layouts.

How It Works

Direct Contact Heating & Mixing

Energy-Efficient Heating

Minimal Temperature Approach

Stable Operation

Automation & Control

Key Advantages

Efficient Crystal Dissolution

Improves molasses quality without dilution.

Energy Savings

Utilizes heat from NCGs or low-pressure vapor, reducing steam and power consumption.

Low Maintenance

Static mixer eliminates mechanical stirrer-related failures and maintenance issues.

Compact & Flexible Installation

Lightweight stainless-steel construction fits easily into existing layouts.

Reduced Pumping Power

Efficient flow design minimizes operational energy costs.

Efficient Crystal Dissolution

Improves molasses quality without dilution.

Compact & Flexible Installation

Lightweight stainless-steel construction fits easily into existing layouts.

Energy Savings

Utilizes heat from NCGs or low-pressure vapor, reducing steam and power consumption.

Reduced Pumping Power

Efficient flow design minimizes operational energy costs.

Low Maintenance

Static mixer eliminates mechanical stirrer-related failures and maintenance issues.

Salient features

Direct heat transfer with vigorous static mixing for uniform conditioning.

Fully automated process control with manual override option.

Compact and lightweight stainless-steel construction for durability.

Minimal temperature approach for maximum energy efficiency.

Handles variable vapor pressures without flooding or agitation.

Applications Across the Sugar Industry

SED’s Molasses Conditioner is ideal for:

Raw Sugar Mills

Refineries

High-Capacity Plants

Multi-Effect & MVR Integrated Plants

Why Partner with SED?

SED combines advanced direct-contact design, static mixing, and process expertise to deliver measurable improvements in energy efficiency, molasses quality, and plant reliability. The Molasses Conditioner ensures consistent operation, reduced maintenance, and seamless integration for modern sugar processing facilities.

Frequently Asked Questions

Revolutionizing Molasses Conditioning. Setting New Standards.

Enhance molasses consistency, optimize energy efficiency, and reduce maintenance with SED’s Molasses Conditioner - engineered for reliable performance, compact design, and seamless plant integration.