Maximize Extraction. Minimize Power Consumption.

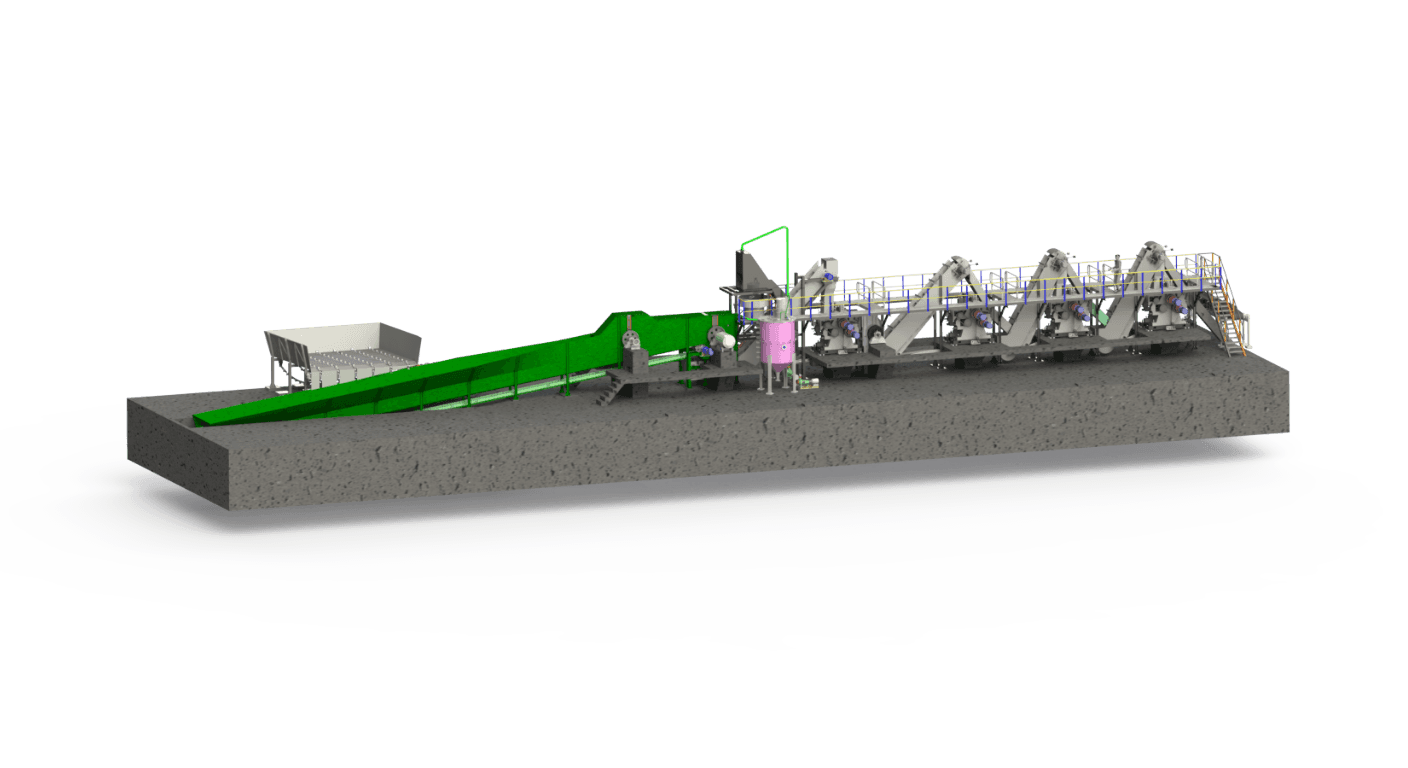

SED’s Milling Systems, also known as Milling Tandems, are precision-engineered units designed to extract maximum juice from prepared sugarcane with optimal energy efficiency. Featuring Three-Roller Mills with independently driven rollers, VFD-controlled motors, and integrated feeding mechanisms like the Toothed Underfeed Roller (TUFR), these systems ensure uniform load distribution, high juice recovery, and smooth bagasse handling.

Built for continuous operation and energy efficiency, SED Milling Systems combine automation, precision engineering, and robust construction to deliver consistent performance while reducing operational costs.

HowIt Works

Cane Preparation

Harvested cane is fed onto a Cane Carrier, then chopped into smaller pieces by the Chopper and Cutter to improve extraction efficiency.

Cane Distribution

Chopped cane is evenly distributed in the Main Rack and directed toward the first mill for crushing.

Milling Process

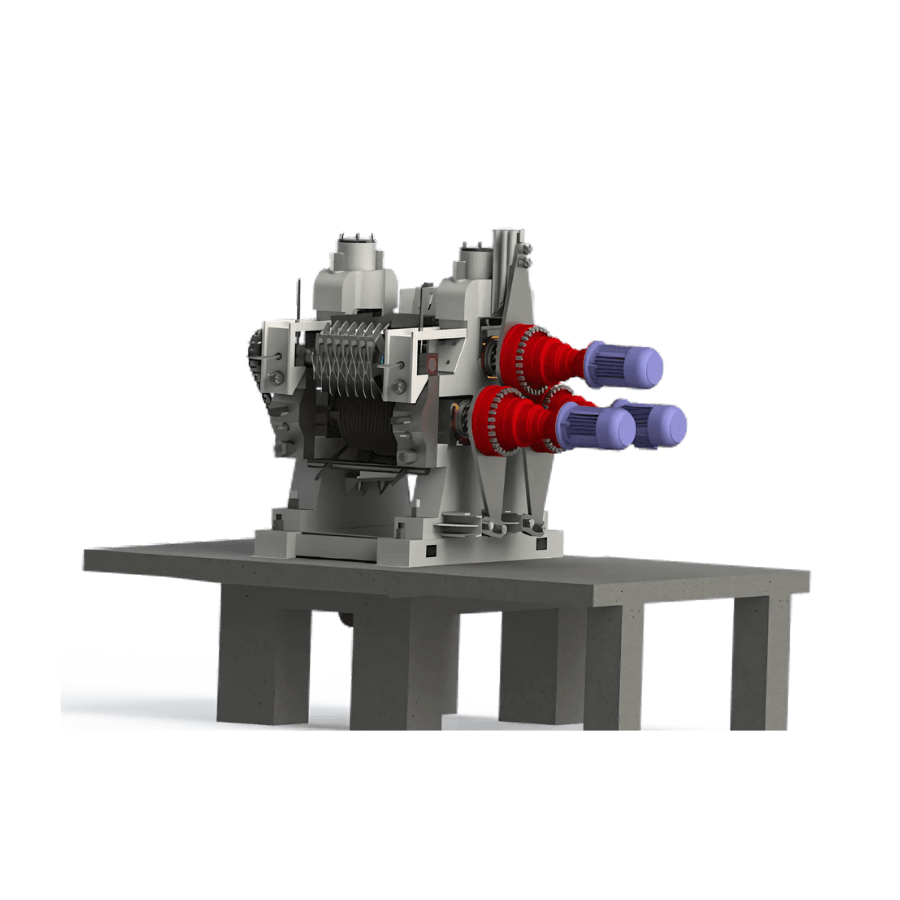

The milling tandem consists of a series of Three-Roller Mills:

- Top Roller : Initiates compression and feeds cane to the lower rollers.

- Toothed Underfeed Roller (TUFR) : Provides consistent grip and feed for uniform extraction.

- Feed Roller (Chevron Grooved) : Ensures steady feeding and reduces slippage.

- Discharge Roller: Smooth bagasse discharge while maintaining optimized juice extraction.

Each roller has an independent VFD-controlled motor, eliminating reliance on energy-intensive main drives.

Sequential Milling

Bagasse is further chopped in intermediate cutters and passed to subsequent mills for enhanced extraction. The number of mills is adapted to plant scale and desired efficiency.

Juice Collection

Extracted juice from each mill is collected and transferred to the Mixed Juice Tank for downstream processing.

Bagasse Handling

Dry fiber (bagasse) is conveyed to storage yards using belt conveyors for reuse or power generation.

Challenges with Conventional Mills

High power consumption

Complex mechanical alignment

Frequent downtime and skilled maintenance

Bulky civil foundation requirements

High power consumption

Frequent downtime and skilled maintenance

Complex mechanical alignment

Bulky civil foundation requirements

SED’s MillDrive System Solution

Compact inline planetary drives

Eliminates heavy foundations and civil structures

Fewer components, spares, and lubrication points

Full automation with low-speed operation (1–4 RPM)

Key Advantages

| Efficiency | Direct Benefit |

|---|---|

| >90% Gearbox Efficiency | Reduced power bills to 10kw/Ton of cane |

| Variable Frequency Drives | Precision milling = Maximum juice extraction |

| Low-Speed Operation (1–4 RPM) | Higher Primary & Reduced Mill Extraction (PME/RME) |

| Fewer Components & Maintenance Points | Lower downtime & OPEX |

| No extra Foundation Required for gearbox and motor | Saved civil costs & faster erection |

| Semi-skilled Operation Feasible | Reduced manpower costs |

| Fully Auto Mode | Consistent performance with minimal supervision |

Streamlined DesignOptimized Savings

Join hundreds of global sugar factories already maximizing their yield while minimizing costs. Contact us today to discuss how Spray’s mill systems can upgrade your operations for the future.